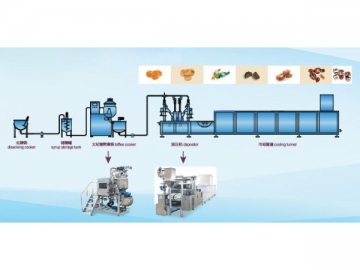

Toffee Candy Depositing Production Line

Request a Quote

The toffee candy depositing production line is designed to manufacture a variety of toffee candy types, including single-color toffee candy, two-color toffee candy, filled candy, and more. Through the use of different molds, different candy shapes are made through a highly automatic production process. This level of automation also saves labor costs.

Features

- The heating time, heating temperature, depositing time and depositing speed are all Mitsubishi PLC controlled.

- The production line is equipped with a 10.7-inch touch screen for display of different parameters, including a flow chart, production line section status, temperature, and depositing speed. It is easy to use.

- The syrup flow is precisely controlled via a frequency control system that ensures a stable sugar paste quality.

- This equipment will add and mix food colors, food flavors, and acid solutions in an online process.

- A chocolate center filing device is optional for the production of chocolate filled toffee.

- With the use of different molds, toffee candies in different shapes are manufactured.

- The production line is customizable to fit unique customer factory conditions.

Standard

- Toffee cooking machine

The toffee cooking machine is designed to cook a variety of candies, including toffee, eclairs, and caramel. Candy is heated via a steam stirring process to effectively prevent charring. - Mold

The production line manufactures candies in different shapes using different molds. We will design molds according to customer needs. - Depositing machine

The depositing machine is composed of depositing head, mold, and refrigerated cooler with the depositing head equipped with a double hopper. By replacing the stamping board and nozzle, this equipment is used to manufacture filled toffee candies. Temperature, depositing speed and other parameters are PLC controlled, with parameters easily displayed and set on the touchscreen. Syrup flow is precisely controlled using the frequency control system to ensure a stable sugar paste quality.

Optional

- Dissolving and mixing unit with automatic weighing system

This system will automatically mix and dissolve glucose, granulated sugar, and other ingredients. Ingredient amounts are strictly controlled via PLC. - Chocolate center filling device

This device is designed for manufacturing chocolate filled candy. It is composed of storage tank, pump, and pipelines. The double-layer storage tank will store chocolate sauce and avoid chocolate solidification. - Fondant rolling machine

The fondant rolling machine is equipped with two rollers made of a jacketed pipe and a whipping stick made of stainless steel. Fondant manufactured using this equipment is a fine, smooth and pure white fondant.