UHMWPE Pipe Production Line

(Composite Pipe Production Line, 50-300mm)

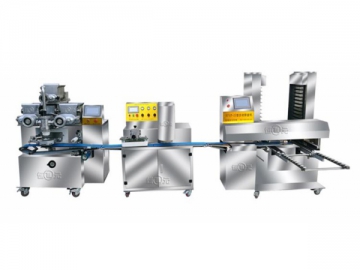

HUAYA developed the UHMWPE pipe production line with own techniques, and the whole production line has got the national patent certificate. This selection of composite pipe production line is designed for the production of UHMWPE pipes reinforced by perforated metal strip. The metal strip mainly made of cold rolled steel greatly improves the composite pipe' wearing and pressure resistance.

Using different kinds of thermalplastic, this UHMWPE pipe production line can produce different pipes for various applications. The reinforced plastic pipes can be used for mining industry, water supply, underground gas conveying, hot water delivery, chemical conveying and some other special applications.

Features of the UHMWPE pipe production line

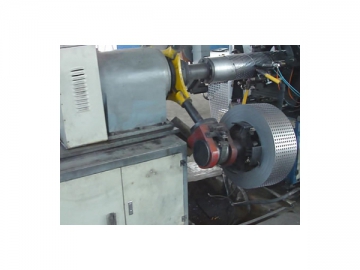

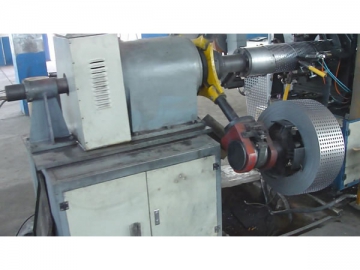

1. The reinforced layer is manufactured using thin walled tube forming technique and argon arc butt welding technique. The shape is accurate and stable, and the welding bead is smooth at both sides. The welding machine, one of the components of the plastic pipe production line, has a big margin of power, and the welding current can change along with the traction speed variation.

2. For the UHMWPE pipe production line, we uses our own composite extrusion die and related extrusion technique. The outer layer and inner layer are extruded by the same extrusion equipment. The perforated metal strip will be coated by both the two layers through small holes in the steel stripe.

3. The electronic control system comes with various premium components like frequency converter, PLC device, temperature controller, button, and so on. All of these components are from famous international companies.

Main technical parameters of the UHMWPE pipe production line| Model | Pipe diameter (mm) | Extruder configuration | Installed capacity (kW) | Water consumption (m3) | Manufacture speed (m/min) | Size (length×width×height) |

| 50-100 | SJ-65/30 | 60 | 5 | 0.5-1.5 | 48×3×2 | |

| 100-200 | SJ-75/30 | 110 | 7 | 0.4-0.8 | 53×3.5×2.5 | |

| 200-300 | SJ-90/30 | 220 | 10 | 0.3-0.7 | 60×3.5×2.5 |