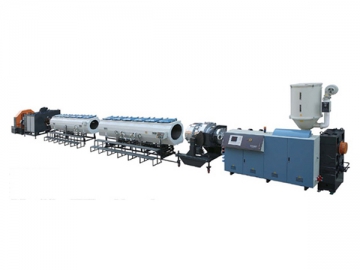

UHMWPE Pipe Extrusion Line

(Wear Resistant Plastic Pipe Extruder, 20-1200mm)

This range of UHMWPE pipe extrusion line adopts vacuum sizing method for production of wear resistant UHMWPE pipes with diameter between 20 and 1200mm. Supporting continuous extrusion, the wear resistant plastic pipe extruder offers relatively higher speed.

Feature

1. Our UHMWPE pipe extrusion line is equipped with a HUAYA patented extrusion screw to offer rational screw speed. This design allows for effective blending and modification of UHMWPE material, realizing continuous and high speed extrusion. Comparing with the plastic pipe extrusion machines using die cooling method, this UHMWPE pipe extrusion line has ten time higher production capacity.

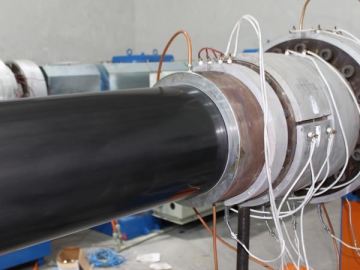

2. The mold comes in flow channel structure with big compression ratio, leading to high strength pipe product.

3. The UHMWPE pipe extrusion line consists of PLC controller, plastic extruder, special mold, vacuum forming machine, traction machine, automatic cutting machine, pipe turning racket.

Utilizing vacuum sizing method, this selection of plastic extrusion machinery is a better solution for producing wear resistant pipes which are often used for conveying fluid, gas, and fluid-solid mixture in the gas, chemical and oil industries, as well as many other kinds of powder, slurry, and gas materials, such as ore, grain, sand, dirt, ash (from power plant), sea/river water, oil, natural gas, chemicals, and so on. Wear resistant pipes produced by this plastic pipe extrusion line can replace the iron pipe, steel pipe, stainless steel pipe, and steel alloy pipe.

Main equipment of UHMWPE pipe extrusion line

1. Ultra-high molecular material extruder

2. Mold

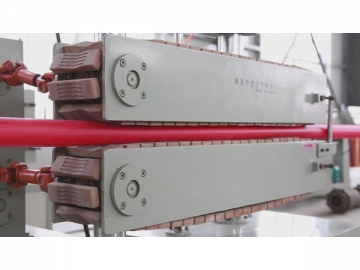

3. Vacuum pipe forming machine

4. Traction machine

5. Cutting machine

6. Pipe bracket

- Ultra-high molecular weight material extruder

- Mold

- Traction machine

- Cutting machine

| Extruder Type | | | | | | |

| Pipe Diameter (mm) | Φ20-Φ75 | Φ110-Φ250 | Φ300-Φ450 | Φ315-Φ630 | Φ630-Φ1000 | Φ800-Φ1200 |

| Extrusion Capacity (kg/h) | 10-50 | 50-100 | 50-150 | 50-220 | 50-350 | 100-450 |

| Installed Capacity (KW) | <50 | <130 | <180 | <220 | <280 | <320 |