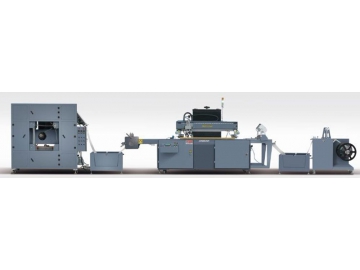

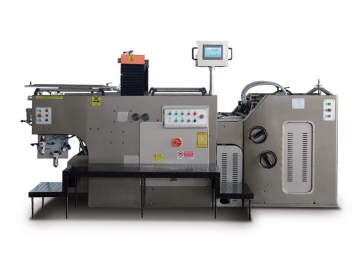

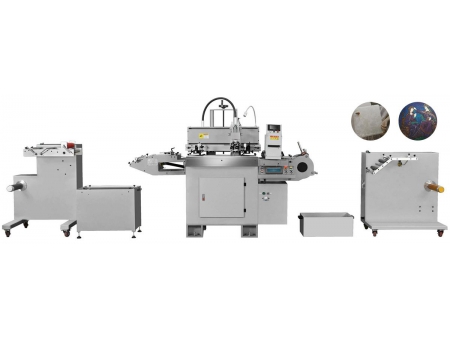

Fully Automatic Screen Printing Machine

Jinbao's fully automatic screen printing machines are made from high-quality steel and castings, featuring complete specifications and abundant functions, which can be widely applied to packing boxes, decorative paper, stickers, anti-counterfeit labels, commercial posters and graphic printing.

Selection Guide

● standard configuration, 〇 optional, - unachievable| Component or function | JB-720A/800A | JB-1020A | JB-1050A | JB-720AG | JB-720/780 | JB-1020 | JB-1050 | Remarks |

| Stop cylinder | ● | ● | ● | ● | - | - | - | |

| Swing cylinder | - | - | - | - | 〇 | ● | ● | |

| Max. running speed | 3600/3300 | 3000 | 4000 | 2200 | 3600/3300 | 3000 | 3000 | |

| No-stop print feeder system | - | ● | ● | - | - | - | ● | ① |

| Front pick up feeder | 〇 | 〇 | - | ● | 〇 | - | - | ② |

| Dust removing devices | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |

| Anti-static devices | 〇 | 〇 | 〇 | ● | 〇 | 〇 | 〇 | ③ |

| Double sheet detector | ● | ● | ● | 〇 | 〇 | ● | ● | |

| Brush wheel and rubber wheel conveying device | ● | ● | ● | ● | 〇 | 〇 | 〇 | |

| Vacuum conveying system | ● | ● | ● | ● | 〇 | 〇 | 〇 | |

| Pull/push convertible side lays | ● | ● | ● | ● | ● | ● | ● | |

| Side lays optoelectronic sensors | ● | ● | ● | ● | 〇 | 〇 | 〇 | |

| Cylinder built-in front lay optoelectronic sensor (Gripper optoelectronic sensor) | ● | ● | ● | ● | - | - | 〇 | ④ |

| Small sheet conveying device | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | ⑤ |

| Squeegee printing pressure kept device | ● | ● | ● | ● | 〇 | 〇 | ● | |

| Ink dropping pan | 〇 | ● | ● | 〇 | - | - | 〇 | |

| Screen frame pneumatic lock clamp | ● | ● | ● | ● | 〇 | ● | ● | |

| Thick sheet anti-rebound device | ● | ● | ● | 〇 | 〇 | ● | ● | |

| Delivery board lowering system | ● | ● | ● | ● | 〇 | ● | ● | |

| Automatic lubrication system | ● | ● | ● | ● | 〇 | ● | ● | |

| Screen frame taken out system | 〇 | ● | ● | 〇 | - | - | - | |

| Crossover delivery stand | ● | ● | ● | 〇 | ● | ● | ● | ⑥ |

| Touch screen with man-machine interface | ● | ● | ● | ● | 〇 | 〇 | 〇 | |

| Safety light curtain | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | ⑦ |

| Backer vacuum pump | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | ⑧ |

Note: partial optional functions or parts require extra charges. If need to, please state it in advance.

- Please order matched curing and delivery system as best as you can.

- Standard feeder configuration: rear pick up

- Feeder uses ion blowing to facilitate to convey electrostatic materials.

- Standard configuration includes two groups and can be increased.

- Can convey paper smaller than the minimum specification.

- Crossover delivery stand

- Light curtain can increase safety factor and protect the personal safety of operators.

- Contains a feeder and two cylinders.

Related products

Send Message

Most Recent

More

Other Products

Videos