Plastic Pipe and Fittings Color Masterbatch (PE, PP, PS, ABS, HIPS)

Application

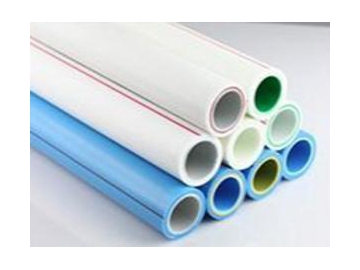

Yudi plastic pipe and fittings color masterbatches are widely used in the manufacturing process of extruding pipe and extruding bar, such as tap- water pipe, gas pipe, pipes of wire and cable and bars of the building materials industry. These products are non-toxic and have outstanding heat resistance and weather resistance.

They can be divided according to carrier materials: PE pipe masterbatch, PPR pipe masterbatch, PVC pipe masterbatch.

Features

This color masterbatch is made from carefully procured high-quality raw and accessory materials processed by an imported banbury mixer continuously. It has good dispersivity and good compatibility. Its surface is smooth and produces no depressions with less die buildup.

| Testing item | Requirement |

| Carrier resin DSC ℃ | 110~130 |

| Carbon black content (mass fraction)% | ≥40.0 |

| Density g/cm3 | 1.20±0.10 |

| Ash content% | ≤3.0 |

| Water content% | ≤0.3 |

| Oxidation induction time OIT(210℃/min)min | ≥20 |

| Melt flow rate (190℃, 5kg) g/10min | As reference for judgment |

| Note: * item is not a qualified criterion. | |

| Testing item | Testing conditions | Requirement | Detection criterion | ||

| Melt mass-flow rate (g/10min) | 230℃, 2.16kg | ≤1.2 | GB/T 3682 | ||

| Melting temperature ℃ | 200℃ | 140-148 | GB/T 19466.3 | ||

| Oxidation induction time (min) | 210℃, 20℃/min | ≥20 | GB/T 19466.6 | ||

| Density (g/cm3 ) | (23±2)℃ | 0.90-1.10 | GB/T 1033.1 | ||

| Ash content % | 600℃ 1h | Porcelain white | ≤20.0 | GB/T 9345.1 | |

| Other color | ≤15.0 | ||||

| Water content % | 180℃ | ≤0.2 | SH/T 1770 | ||

| Weather resistance | UV light weather resistance | 40W*2, 140h | △E≤5.0 | Standard 6.7 | |

| Xenon lamp weather resistance | 300h | △E≤5.0 | GB/T 16422.2 | ||

| Heat-resistance temperature℃ | | ≥240 | Standard 6.8 | ||

Storage and transportation

Packing category: paper plastic compound bag (25KG/ bag)

Packing method: artificial weighing. 25KG is a packing unit.(We can also use small package like1KG for special requirements)

Cautions during transportation: The package should be secured when loaded and transported. Ensure that the package is not leaking, collapsed, fallen, or damaged. Also, do not mix the masterbatch with oxidants during transportation. Exposure to the sun, rain, or high temperatures should also be avoided.

Cautions during storage: The package should be stored in a cool and ventilated storage area. Keep away from fire and heat sources as well as oxidants. Fire-fighting equipment should be kept nearby as a precaution.

Since 1996, Yudi has been manufacturing plastic colored material, masterbatch, for coloring resins like PE, PP, PS, ABS coloring, the colored plastic can be used as film bag, plastic case, plastic toy and furniture, even wire and cable insulation shield of plastic and all plastic product colored, we have plenty of material and enough equipment of manufacturing various masterbatch to meet different client needs.

Index

plastic masterbatch, master batch, polymer, plastic additive, colorants