Rotary Drilling Rig Kelly Bar

RotaryDrilling Rig Kelly Bar

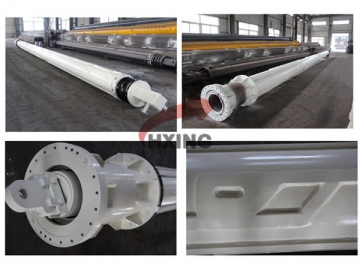

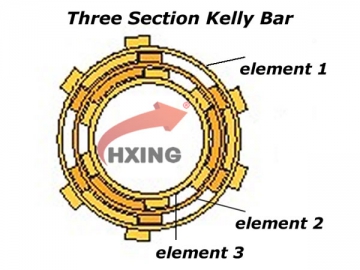

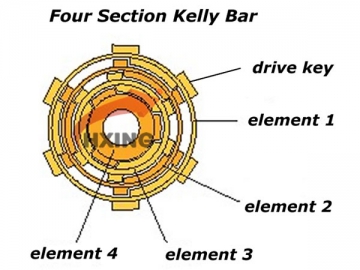

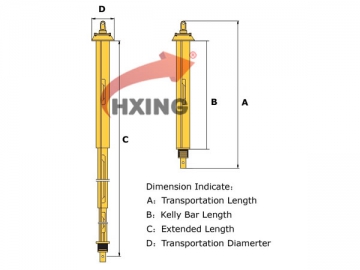

Kelly bars are a key component on hydraulic rotarydrilling rigs. They transfer the torque of the rotary drive and the crowdpressure of the crowd system concurrently to the drilling tool. Our kelly barsconsist of 3-6 telescopic tubular sections with a system of drive keys and lockrecesses that have been welded onto the outer surfaces. Standard kelly bars areproduced with a total of 6 drive keys on each section. The tubular kellysections are manufactured from high tensile steel to ensure the minimum weighthas the right strength for different applications.

Locking kelly bar systems are designed specificallyfor drilling into hard materials and when a crowd force application isrequired. Locking kelly bars come with drive rails designed with lockingpockets on their length, and corresponding terminal joint locking points. Thepurpose is to interlock each telescopic element to the inner following one inorder to apply the maximum torque and crowd force developed by the base rig.

Due to that, the rotary table inner drive is alsoequipped with locking pockets. When extracting the locking bar from down thehole, the combination of lifting and rotating clockwise allows the telescopicelement to unlock. Locking bars are usually supplied with 3 or 4 telescopicelements.

A friction kelly bar gets its name from the method bywhich is transfers torque to the drilling tool. The telescopic elements areadvanced using ‘frictional contact’ from each of the friction drive rails thatrun down the outside of each kelly bar. These drive rails are driven by therotary table and the terminal joints of each successively larger in diameterkelly bar. The terminal joint is a long piece on the inside and at the bottomof the kelly bar.

Friction kelly bars are normally available with 3, 4,5 or 6 telescopic elements as they are primarily used for deep piles in mediumhard soil conditions.

· Telescopic pipes steel quality: Q345B

· Drive rails steel quality: German imported steel plate

· Drive stub steel quality: Special forged steel

· Drive stub dimensions: 200x200, 150x150 or customized

· Outer pipe available diameter: 254, 292, 298, 305, 343, 368, 378, 445…

· Upper shock absorber: Damping rubber ring

· Lower shock absorber system: Damping rubber ring and damping spring

• Telescopic elements Number: 3, 4, 5, 6 others on request

Kelly Bar Performance and Characteristics

1. Use of advanced international six-key distributiontechnology and standard modular design.

2. With the use of advanced processing equipment,processing technology and unique tooling manufacturing processes, our kelly barcan be used on different drilling machine brands, including XCMG, CSR, SANY,SOILMEC and others.

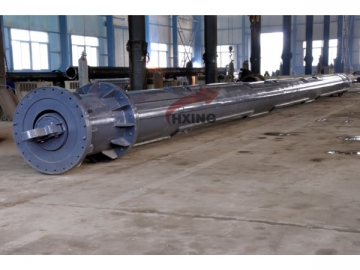

3. The entire kelly bar set is light weight, highstrength, high linearity of the single section and the pipe wall, there is asmall seam between sections, and there is an excellent wear resistance on thekey plates, meeting the specific requirements for rotary drilling machines.

4. Our kelly bars are manufactured with seamless steelpipes that have been specifically customized using high quality domestic alloysas well as German imported high-strength seamless steel pipes to ensure thedimensional accuracy, position error, mechanical properties and excellentweldability. The small pipes use an alloy hydraulic prop tube, which, with asecondary processing features a strength that can reach more than 800Mpa.

5. The outer keys are made of alloy steel, giving themtheir high hardness, high toughness and excellent welding performance. After aspecial heat treatment, the wear resistance is significantly improved, in orderto reduce failure rates and maintenance costs.

6. We have three types of kelly bars: interlocking, frictionaland combined. The length of the kelly bar depends on customer requirements orthe drilling machine parameters. Kelly bars with different torques can bepaired with different rotary drilling rig models. Lifting lugs and square headshave multiple connection methods available for users.

7. Complete material specifications ensure we canprovide kelly bars for any domestic or imported rotary drilling rigs. Eachkelly bar features a full torque and maximum drilling depth of 100meters.

8. Long term maintenance is supplied on all kellybars, and we have the experience necessary to carry out on-site maintenanceservices.

In addition to high quality products, we also providethe following services:

1. We have outstanding after-sales services and keep arecord of all material sources and manufacturing processes. We also keep spareparts available.

2. Starting from the date the drilling rig leaves the factory,we provide videos for trouble shooting or paid maintenance services forcustomers.

3. We provide spare parts for maintenance services onthe kelly bars at a favorable price.