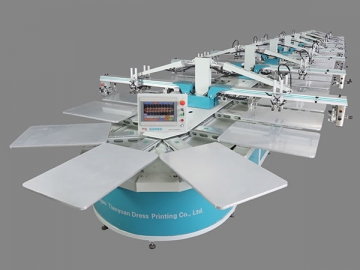

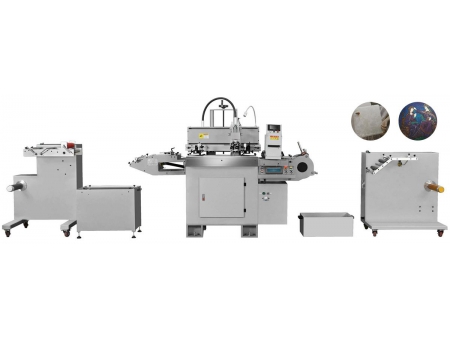

Screen Printing Press (Oval Shape)

The TYSL with its modular design, expandable configurations and large print area is one of the most versatile and multi-functional screen printing presses on the market today. This oval shaped screen printing press takes up less floor space than a traditional comparable carousel screen printing press.

The TYSL model screen printing press can place a variety of colors using different colorants (water based ink, thermosetting ink, flocking adhesives, discharge inks, plastisol ink and pre-dried ink for hot stamping) onto cut pieces and finished garments. Using flocking technique, our oval-shaped printing press is equipped with printhead, thus screen printing, flocking, and digital printing can be carried out simultaneously. It's a good choice among customers due to its durability, print quality, multi-function and easy to use design.

Our oval shaped screen printing machine comes with 6 to 24 printheads. Each station is able to place a single color on the textile material, and its maximum image area is 840mmx1100mm. Its convenient modular design allows for expansion, which means the screen printing press operator can start with as few or many printheads and print stations needed for a particular task, and add or subtract more as their needs change.

High strength aluminum alloy gives the printing press its rigidity, quality and durability. A sophisticated servo-drive rotary system delivers a high printing speed at a smooth operation, precise color registration, and maximum reliability.

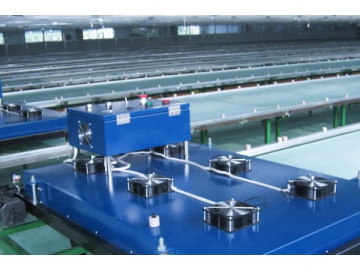

Screen Printing Press Parts- Partial view

- Partial view

- Touch-screen Control Panel

- Print-head

- Operational keys

- Control keys

Features of the Screen Printing Press

1. Multiple print stations are arranged in an oval shape. A modular design allows the addition of print heads and stations.

2. A single print head corresponds to several pallets. The pallet, also known as a platen, is where the textile material is placed for printing. This configuration makes the most efficient use of the print heads possible.

3. A reliable servo drive is used for an independent, precise positioning, which ensures consistent print quality.

4. A flexible, convenient screen clamp ensures a tight grip on the screen frame for an accurate match to the pallet.

5. The touch screen interface and advanced control panel are used for independent control of each print head for a more convenient operation.

6. A friendly after-sales service team ensures customer peace of mind.

7. Strong aluminum alloy pallets allow for a maximum image area of up to 840×1100mm.

| Model no. | TYSL-the number of print-heads |

| No. of print-heads | 6-24, as per customer requirements |

| No. of pallets per print-head | 2-6 pallets |

| Print size (cm) | 45×45cm ~ 84×110cm |

| Power supply spec | 380V/50Hz |

| Main power (kw)* | 6-12 print-heads: 1.5kw, above 12 print-heads: 2kw |

| Power of per print-head | 0.37 |

| Minimum air pressure (Mpa) | 0.6 |

| Flash cure unit power (Kw/set) | 12--16 |

| No. of Colors | Equal to the number of print-heads |

| Maximum print speed (pcs/h)** | 900 |

**NOTE

1. A single asterisk (*) the main power excludes the power consumption of flash dryer and print heads.

2. A double asterisk (**) indicates that the print speed refers to the speed of the squeegee moving across the screen in one stroke.