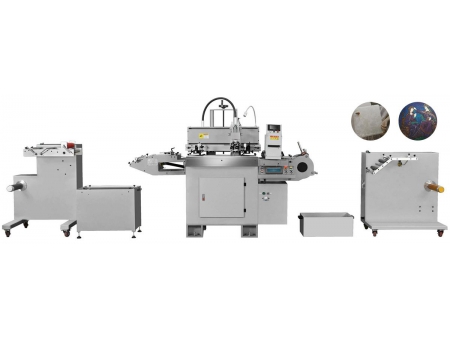

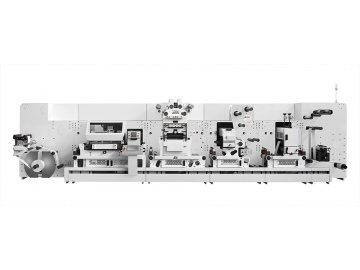

Screen Printing Machine (Flat Bed)

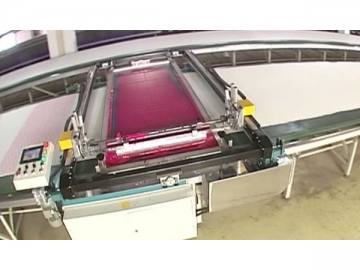

This screen printing machine is a true flatbed printer, as opposed to a moving media printer, as it holds the textile substrate (material) stationary while allowing the print head to move across the long, flat table. With the use of a digital positioning system, the print head can be accurately located and place the right color in the correct spot.

The flatbed screen printer does require the ink to be added manually to the back of the screen, making the process slightly labor intensive. However, compared to traditional, manual flatbed printers, this semi-automatic unit saves significant labor costs.

Whether you are just starting in the screen printing business, or looking to expand your existing production, the industrial flat-bed screen printing machine is an excellent choice for printing accuracy and flexibility. Its high automation level also frees up employees to carry out other tasks.

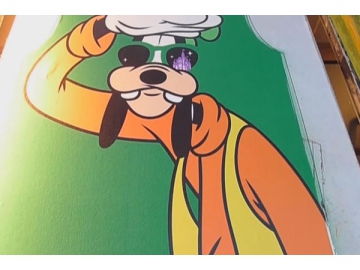

The screen printing machine can print on nearly any material, including woven fabric, nylon, sheet metal, plastic sheets, marble, ceramic, glass and cartons. The presses themselves can be both sheet and roll fed.

Our flatbed printer also comes with a moving print head, which can travel freely from one flat table to another without manual intervention or the aid of tools. This feature is convenient, as it enables an easy changeover, improving printing rates. The servo-drive squeegee assembly ensures evenly distributed pressure during the ink application. The mechanism also allows for an easy pressure adjustment.

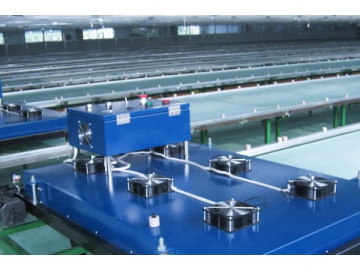

The textile printing machine is often custom built to customer specifications of production requirements and workshop environments. Customers can request several flat tables that are parallel to each other, with each table providing choices in length from 1 to 60 meters, depending on the size of your print shop. The table width should be decided based on the size of the most frequently used textile substrates.

For customers who prefer multiple long tables, we suggest equipping each table with a single print head, in order to achieve maximized print quality and rates. One print head generally comes with a single screen frame. However, extra screen frames for your screen printing machine are available upon request.