Cast Film Line (350m/min)

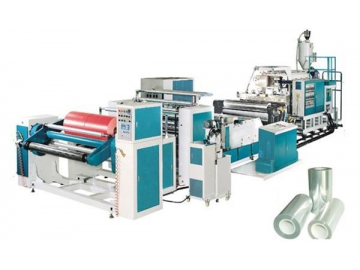

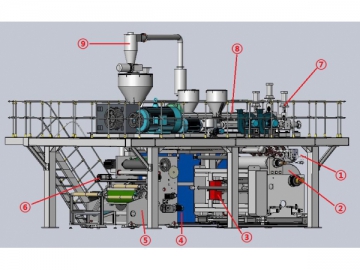

The high speed stretch film extruder is our latest generation stretch film production line and features a high line speed, allowing for a high production output at a maximum of 400kg/h. This stretch film production machine utilizes LLDPE and LDPE granules to produce the casting stretch film, which is then widely used for packing building materials, pallet wrapping, wrapping auto parts, hardware tools and more. The film extrusion machine is equipped with extruders, a T die and distributor, thickness gauge system, leveling part, traction component, edge trimming and recycling component, automatic cutting and winding component and an electric control system.

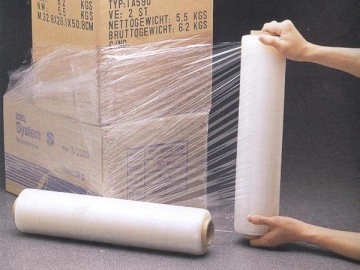

High quality finished products

Traditionally, the more layers there are to a cast film, the stronger the film is. This cast film line uses triple screw extruders, which are capable of producing up to 7 layers of cast films.

Breakthroughs in production speed

All of the cast film machines are computer controlled with an easy man to machine interface. The actual production line speed reaches up to 250 meters/minute.

High stability

In order to adapt to high speed equipment operation, we thickened the machine’s fame, bringing the machine weight up to 25 tons in order to ensure both the stability and low noise levels during high speed operation.

- A JC-times screw die is used to ensure the product thickness uniformity, and sticks on just a single film side so as to not waste glue.

- An 828mm double cold roll ensures high precision at high speed.

- The online thickness gauge is used to monitor the wrapping film thickness. Once the thickness deviation occurs, operators can immediately adjust the screw die in order to effectively avoid product wastage.

- All bearings are from the Japanese NSK brand to ensure the roller’s stability.

- This equipment uses a servo motor and PLC to achieve a friction winding and ensure the equipment stability.

- This equipment uses a servo motor to control flying cutter trimming with a high speed and high stability in order to avoid wire drawing when changing the coil.

- The fast changing film system is controlled by the hydraulic system for a high efficiency.

- The machine uses a central module temperature control which breaks from traditional 95% precision of the temperature control, and provides a 100% accurate temperature control to meet all high speed production requirements.

- This cast film line will automatically recycle the edge strips online, thus saving production costs. Recycling is computer controlled, thereby reducing labor intensity and improving the production efficiency.

| Model | JDCPE120/80/70-1000 |

| Diameters of screws | F120mm F80mm F70mm |

| Ratio of length to diameter | 33:1 |

| Product widths | 1000mm(500´2 rolls) |

| Product thickness | 0.01-0.03mm |

| Actual working speed | 250m/min |

| Mechanical design speed | 350m/min |

| Maximum yield | 400kg/h |

| Main motor power | 110kW 45kW 30kW |

| Total power | 360kW |

| Sizes | 7290mm´5650mm´4000mm |

| Weight | 25000kg |

| Power supply | 380V/3P/4L/50Hz |

- The machine shape and technical parameters are subject to change without warning as we continuously upgrade our equipment.

- The cast film line can be customized according to customer requirements. The production width of the cast film line can be customized in a range of 1 to 1.5 meters, and the number of layers customized between 3 to 7 layers to meet different market needs.

- Cast film lines with different specifications can also be customized.

For machinery wrapping

For machinery wrapping  For hand wrapping

For hand wrapping  For pallet wrapping/machine protection packing for shipping

For pallet wrapping/machine protection packing for shipping

For pallet wrapping/machine protection packing for shipping

For pallet wrapping/machine protection packing for shipping  For pallet wrapping/machine protection packing for shipping

For pallet wrapping/machine protection packing for shipping  For fresh food/fruit/salad packing

For fresh food/fruit/salad packing

For fresh food/fruit/salad packing

For fresh food/fruit/salad packing - For fresh food/fruit/salad packing

- Magical use: For loosing weight