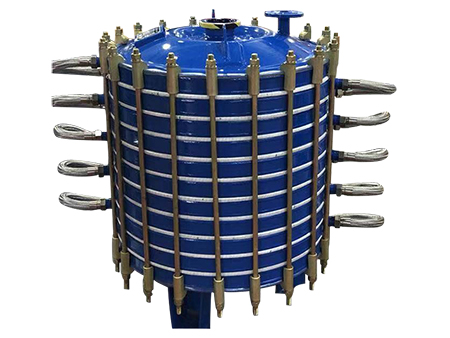

SEC Evaporative Condenser

Working Principle

Through heat-exchange with the spraying water and air outside of the condenser coil, the high temperature gaseous refrigerant in the coil will be condensed into liquid. The strong air generated by the draught fan enables the spraying water to cover on the coil surface with maximized covering area, which amazingly improves the heat exchange efficiency.

After absorbing heat, the spraying water and air has increased temperature. Thus, some of the water is evaporated into water vapor, during which large quantity of heat is required. The water vapor in the hot air is caught by a baffle board, and is then delivered to the PVC heat exchange layer in which the water vapor is cooled and collected by the water collecting sump. Finally, the water in the sump will be pumped into the water spraying system, and next cycle starts. The water vapor in the air is controlled by a water level controller. The capacity of the SEC evaporative condenser can be adjusted to suit varied load demands, by changing the motor speed, or using varied motor and fan combinations.

Unique and User-friendly Structure Design

The spacious interior space ensures easy maintenance. Built based on our decades of operation experience, the product also offers super long service life.

Directly Examinable and Repairable Water Spray System

Due to the air and water flow in the same directions, the evaporative condenser supports exposed water spray system. This allows for quick examination and maintenance of the spray nozzles and coils even when the SEC is in operation.

Wide-Spaced, Non-clog Air Inlet Louver

Due to the wide-spaced and high quality air inlet grille design, the possibility of scale-forming and icing on the air inlet louver is minimized.

Hinged Access-Doors for Easy Entry

A large-sized access door at one end of the evaporative condenser unit provides easy access to the interior of the unit, which ensures convenient maintenance.

Easy Access to Fan Drive System and Condensing Coil

The motor drive system and the condensing coil can be easily maintained, because of the removable baffle board.

Sloped Water Collecting Sump Bottom Facilitates Cleaning

The floor of the water basin is sloped toward the depressed section and the wet deck is elevated to facilitate flushing dirt and debris from this critical area.

The bottom of the water sump is inclined to the sewage draining exit. This coupled with the suspended design for the PVC heat exchange layer, ensures easy cleaning of the sewage water and impurities.