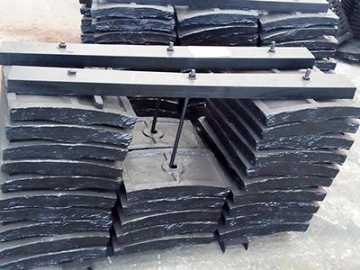

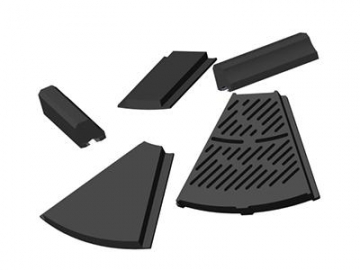

Manganese Steel Ball Mill Liner

Introduction

We can customize ball mill liner for customers, whose hardness is more than HRC45-55, impact toughness is over 25J and service life is two times than common liners.

The function of wearable liner is to prevent the cylinder body from being directly hit by grinding media and materials and corrosion and wear of slurry.

Liner material quality: high manganese steel liner, chrome alloy liner, carbon chrome molybdenum alloy steel liner.

Chemical composition

| Name | Chemical composition (%) | |||||||

| C | Si | Mn | Cr | Mo | Ni | P | S | |

| High manganese steel liner ZGMN13 | 0.9-1.5 | 0.3-1.0 | 11-14 | 0-2.5 | 0-0.5 | ≤0.05 | ≤0.1 | ≤0.05 |

| Name | Surface hardness (HB) | Impact value (J/cm2) | Metallographic structure |

| High manganese steel liner ZGMN13 | ≥300 | ≥80 | M+C+P |

| M-martensite C-carbide P-pearlite | |||

| Size | Aperture (mm) | Liner length (mm) | ||

| ≤40 | ≥40 | ≤250 | ≥250 | |

| Tolerance | +2 0 | +3 0 | +2 | +3 |

Related products

Send Message

Most Recent

More

Other Products

Videos