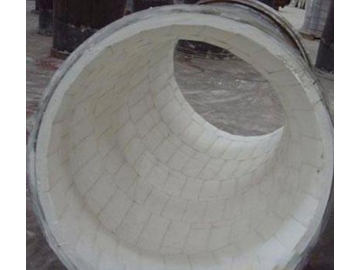

Ceramic Ball Mill Liner

Introduction

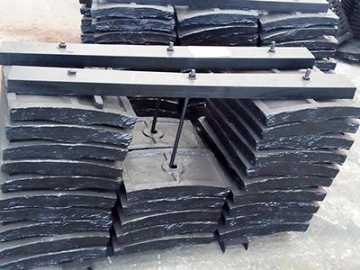

We can provide customers with customized ceramic ball mill liner. The function of ceramic ball mill liner is to resist the impact on the inner side of the cylinder during the grinding process, so as to reduce the wear on the equipment units.

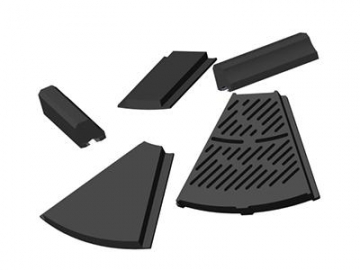

| Name | Length(L)mm | Upper side width (W1) mm | Lower side width (W2) mm | Thickness (H) mm | |

| Straight brick | 150 | 50 | 50 | 40/50/60/70/80/90 | |

| Diagonal brick | 150 | 45 | 50 | 40/50/60/70/80/90 | |

| Straight half brick | 75/37.5/18.75 | 50 | 50 | 40/50/60/70/80/90 | |

| Diagonal half brick | 75/37.5/18.75 | 50 | 50 | 40/50/60/70/80/90 | |

| Thin brick | 150 | 22.5 | 25 | 40/50/60/70/80/90 |

- The content of alumina is 92%, which is high purity and will not pollute grinding materials.

- Ceramic ball mill liner has good wear resistance, which is 266 times than manganese steel and it has long service life.

- The output slurry is finely ground.

- It has the features of corrosion resistance, high density and high mechanical strength.

Related products

Send Message

Most Recent

More

Other Products

Videos