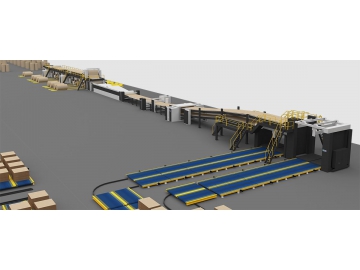

Glue Machine for corrugated cardboard production

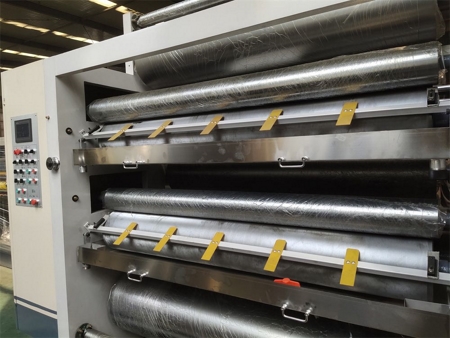

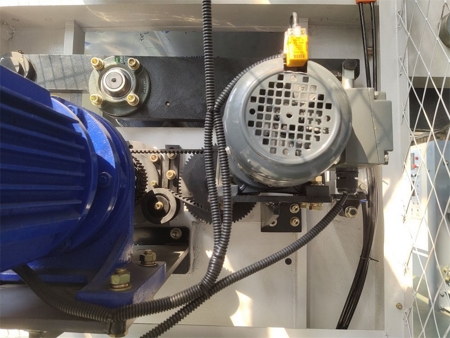

Glue machine is specially designed to coat corrugated paper, gray board and others with glue. Its emergence offers great convenience for glue coating, and is warmly welcomed by the market. The corrugated cardboard gluing unit is generally composed of large/medium/small chrome-plated rolls, rack, gears, pulley, motor, adjusting wheel and etc. Driven by an electric motor, the glue unit’s gears operate with the help of pulley. Then chrome-plated rolls of different sizes rotate to make sure that the small roll collects glue from the glue pot and the doctor roll distributes it evenly on the roll surface.

| Paper Width (mm) | External Dimensions (L×W×H) (mm) | Weight (T) | Whole Machine Power (kW) |

| 1400 | 1450×1830×2915 | 7.4 | 10 |

| 1600 | 1450×2030×2915 | 7.8 | 10 |

| 1800 | 1450×2230×2915 | 8.2 | 10 |

| 2000 | 1450×2430×2915 | 8.6 | 10 |

| 2200 | 1450×2630×2915 | 9.0 | 10 |

- Max. machine speed is 220m/min;

- Glue applicator roll and metering roll are both of modular and built-in design. They can be installed and detached from the operation side, easy for repairing and maintenance;

- Glue unit’s arm can be locked for rider roll’s stable and reliable working under high speed operation;

- Gaps between glue applicator roll and metering roll can be automatically adjusted according to the speed, paper characteristics and flute types;

- Rider roll is adopted to exert compression. The gap between rider roll and glue applicator roll can be electrically adjusted, thus to achieve the fast changeover and process paper boards of different flute types;

- Pneumatic lifting design of glue pot facilitates its cleaning. And glue blocking plates are designed on both sides of the glue pots, well preventing the splashing of glue when glue applicator roll and metering roll work at a high speed;

- Layered frequency conversion motors and pulleys are adopted, so the controlling is respectively independent, the driving precision is high, and the vibration and noise during operation are largely reduced;

- Different layers are independently adjusted. The corrugated cardboard gluing machine uses man-machine interface display, so the adjustment and controlling are more flexible and easy;

- Electrically adjusted floating roll is optional to facilitate paper feeding and contact angle adjustment;

Related products

Send Message

Most Recent

More

Other Products

Videos