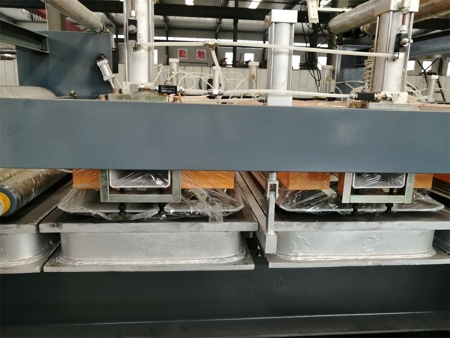

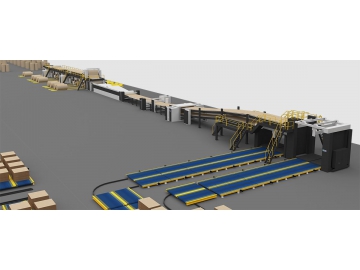

Double Facer for corrugated cardboard production

Double facer is a major unit in corrugated cardboard production line. It is mainly designed for bonding, heating, drying and cooling of the single faced corrugated cardboard and paper, thus to produce quality three, five or seven layered corrugated cardboard. Besides, it also feeds corrugated cardboard to slitter scorer and other machines for further processing.

| Working Width | 1000-2500 mm |

| Steam Pressure | 0.8-1.3 Mpa |

| Air Pressure | 0.6-0.9 Mpa |

| Up Drive Roller Diameter | 400/600/800 mm |

| Down Drive Roller Diameter | 400/600/600 mm |

- Number of hot plates: 16, 18, 20 and 22;

- Two sets of conveyor belts with tension control device;

- Lower conveyor belt’s tension control device is fixed vertically, which facilitates the adjustment;

- Hydraulic lifting devices are built inside;

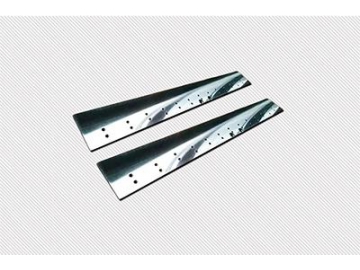

- The hot plates are ground and chrome plated. Double facer’s hot plates are also in accordance with national pressure vessel standards. The certificates are also offered for our customers;

- Pneumatic pressure adjustment can be carried out through three stages according to the thickness of cardboard;

- Steam pipe is well located, allowing grouped temperature adjustment of hot plates;

Related products

Send Message

Most Recent

More

Other Products

Videos