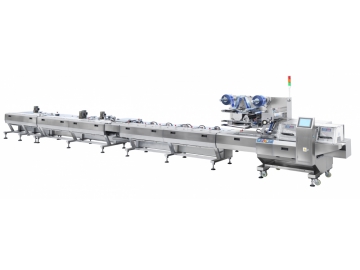

Flow Packing Machine

Introduction

Flow Packing Machine is adaptable to various composite films, paper films, aluminum film and other materials in order to pack a wide array of solid and regularly shaped objects. It features an advanced design and durable structure. The wrapping machine is controlled using a PLC computer, and the main motor speed uses variable frequency stepless regulation. All finished products feature a clear seal and excellent sealing properties.

Range of application

It is suitable for packaging a variety of food, including biscuits, moon cake, candy, bread, instant noodles, ice cream and more, as well as packaging daily necessities and hygienic products, such as soap, tape, napkin and disposable utensils, and finally, it is also suitable for repackaging of various medicines and items bundled together in trays.

- This equipment features dual inverter control. The bag length can be pre-determined, then cut to the specified length. Users do not need to start the machine for debugging in advance, as it can be done in a single step, saving materials.

- It features an easy to use man to machine interface, where it is easy to set parameters.

- The machine features a self-diagnosis function, allowing users to easily diagnose any problems that arise.

- A highly sensitive photoelectric color tracking is used, as are digital input controls for the sealing position, making the machine highly accurate.

- There is an independent PID controller, which is capable of adapting to different packaging material types.

- This equipment will stop in the expected position, and the blade features a non-stick performance, thus saving materials.

- The transmission system is simple, making operation and maintenance easy.

| Wrapping speed | 60-150 packages/min(according to materials) |

| Size(double blade) | L(60-190)x W(30-110)x H(2-40)mm |

| Size(single blade) | L(120-380)x W(30-110)x H(2-60)mm |

| Maximum width | 250mm |

| Power supply | AC220V 50Hz, 2.5Kw |

| Weight | 700kg |

| Overall dimension | 3350 x 650 x 1550mm |