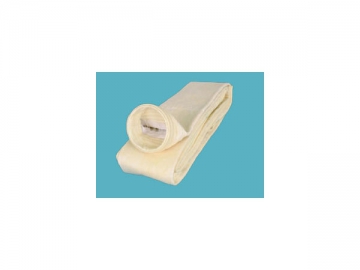

FMS Composite Needle Felt Filter Bag

As a highly efficient filtration material with a reasonable design and excellent performance, the FMS composite needle felt filter bag is often a first choice in a wide range of industries, including steel and iron working plants, chemical industries, cement factories, waste incineration, asphalt processing stations and more.

Product Features 1. The FMS filter bag features an outstanding abrasion resistance, excellent flexibility and a great dust collection capacity. It is able to handle large working loads and a filtration speed of at least 1.5m/minute, ensuring a significant improvement in the mechanical strength, filtration efficiency, filtering speed and powder collection performance.

2. Our filter bag meets the needs that traditional filtration materials can’t meet, such as an elongation level that is too high, evident deformation and a poor corrosion resistance.

3. The compact design and high strength leads to a relative decrease in the initial resistance and operating resistance, thus prolonging the service life.

4. This composite needle filter bag also features an excellent thermal resistance, flame repellant performance, corrosion resistance, and a very small gas resistance. Compared to traditional woven fabric, it has a 100% faster filtration speed.

5. After undergoing a series of different chemical treatments, the FMS filter bag is easy to clean, waterproof and static resistant.

Technical Data of FMS Composite Needle Felt Filter Bag

| Product Name | FMS composite needle felt filter bag |

| Fiber composition | E-glass filter P84 P84 fiber Kevlar |

| Scrim composition | E-glass filter fabric |

| Weight(g/m2 ) | 900 |

| Width(cm) | 40-200 |

| Thickness(mm) | 2.30 |

| Air permeability(10-3 m3/s/m2) | ≥180 |

| Continuous service temperature( ℃) | 240-250 |

| Surge temperature ( ℃) | 280 |

| Filtering speed (m/min) | 0.8-1.2 |

| Chemical stability | Alkali: Excellent Acid: Excellent |

| Treatment | PTEE dipping, coating, water proof |