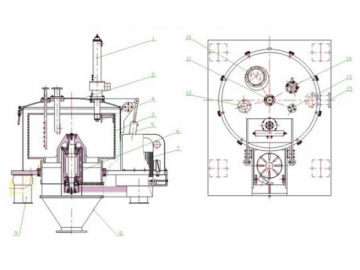

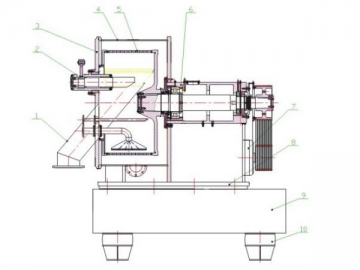

Vertical Scraper Centrifuge

- L(P)GZ Series Vertical Scraper Centrifuge

- L(P)GZ-F Series Vertical Scraper Centrifuge

Feature

1. The L(P)GZ/L(P)GZ-F vertical scraper centrifuge allows easy opening of its cover or even the entire housing, and this brings extra convenience for machine cleaning and maintenance.

2. This vertical bottom discharge centrifuge has a fully enclosed structure, and its process area, bearing seat and scraper knife are well protected by nitrogen gas.

3. Despite of the simple structure, all welding joints are very smooth and easy to clean. Moreover, machine surface is perfectly polished, and the surface roughness (Ra) reaches up to 0.2-0.4μm.

4. To offer reliable performance, the main shaft is well sealed and is monitored by a specialized inspection device to prevent leakage.

5. As a result of the reasonably designed CIP system, our vertical scraper centrifuge can be cleaned effectively and with minimal effort.

6. High temperature sterilization can be performed to make internal parts more hygienic.

7. Our vertical pharmaceutical centrifuge is fitted with a frequency converter, and it adopts regenerative braking or dynamic braking.

8. A fully enclosed housing is employed by the transmission system so as to reduce particulate matter emission during work.

| Model | |||||||||||

| Drum diameter (mm) | 800 | 1000 | 1000 | 1200 | 1250 | 1250 | 1500 | 1600 | 1600 | 1800 | 1800 |

| Drum height (mm) | 400 | 420 | 580 | 500 | 500/630 | 800 | 700 | 800 | 1000 | 800 | 1000 |

| Drum capacity (L) | 100 | 140 | 190 | 260 | 310/400 | 505 | 610 | 800 | 1000 | 1000 | 1250 |

| Max. loading capacity (kg) | 135 | 180 | 250 | 320 | 400/520 | 650 | 820 | 1000 | 1200 | 1200 | 1600 |

| Drum speed (r/min) | 1500 | 1080 | 1200 | 970 | 1000 | 1000 | 850 | 850 | 850 | 800 | 800 |

| Max. separating factor | 1007 | 652 | 805 | 631 | 698 | 698 | 605 | 646 | 646 | 645 | 645 |

| Motor power (kW) | 7.5 | 15 | 15 | 18.5 | 18.5 | 22 | 30 | 37 | 45 | 55 | 55 |

| Machine size with shock absorber (mm) | 1700×1400 ×1800 | 1968×1500 ×1900 | 1968×1500 ×2100 | 2280×1800 ×1977 | 2280×1800 ×2354 | 2280×1800 ×2563 | 2600×2140 ×2563 | 3000×2400 ×2800 | 3000×2400 ×3210 | 3260×2300 ×3100 | 3230×2630 ×3200 |

| Weight (kg) | 2000 | 3500 | 3800 | 4350 | 5000/5600 | 6000 | 10800 | 12500 | 12800 | 14450 | 16000 |

| Model | ||||

| Drum diameter (mm) | 800 | 1000 | 1200 | 1250 |

| Drum height (mm) | 400 | 420 | 500 | 500 |

| Drum capacity (L) | 100 | 140 | 260 | 313 |

| Max. loading capacity (kg) | 135 | 180 | 320 | 400 |

| Drum speed (r/min) | 1500 | 1080 | 970 | 1000 |

| Max. separating factor | 1007 | 652 | 631 | 698 |

| Motor power (kW) | 7.5 | 15 | 18.5 | 18.5 |

| Machine size with shock absorber (mm) | 2000×1400×1330 | 2480×1500×1280 | 2558×1800×1445 | 2658×1800×1550 |

| Weight (kg) | 3100 | 4730 | 5700 | 6200 |

Main Material

1. Flat plate: Q235 lined with stainless steel

2. Drum bottom: Cast steel lined with stainless steel

3. Cover, housing and their attachments: Stainless steel

4. Drum (except its bottom): Stainless steel

5. Bearing seat: Cast iron or cast steel covered by stainless steel

Standard Structure

With a platform structure, our vertical scraper centrifuge integrates its housing and base plate together via welding, and its cover and housing are connected by flanges. There are many devices on the cover, like feed pipe, wash pipe, viewing light, scraper knife and manhole, and all the pipes are connected by standard flanges.

Standard Configuration

1. Frequency converter and PLC controller

2. Dynamic braking

3. Fill level controller (contact type)

4. Common vertical (or explosion proof) motor

5. Common V-belt, safe cover and motor cover

6. Operation box

7. GERB shock absorber

Structural Option

1. Flange connected housing and base plate, fast locking mechanism with reliable seal

2. Stainless steel drum

3. Air outlet, etc.

Parameter Option

Based on customer requirements, this scraper centrifuge may come with different specifications:

1. Drum volume (maximum loading capacity)

2. Revolving speed (maximum separating factor)

Configuration Option

1. Common (or explosion proof) motor with fixed torque

2. Anti-static (or other type) transmission belt

3. Regenerative braking system

4. LCD touch screen

5. Vibration protection, inert gas (nitrogen) protection

6. Revolving speed indication

7. Oxygen content detection or nitrogen feeding control

8. Cover opening protection

9. CIP system and high pressure gas back washing system

10. Non-contact fill level control

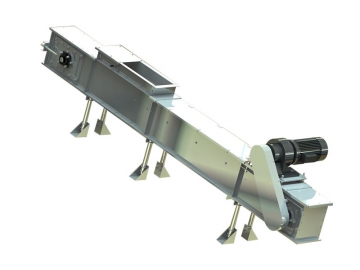

11. Inclined feed distributor

12. Residual heel removal system (patented)

13. Other devices

| 1. Scraper Cylinder 2. Cover 3. Drum 4. Scraper 5. Housing | 6. Bearing Seat 7. Motor 8. Collective Hopper 9. Shock Absorber 10. Manhole | 11. Feed Pipe 12. Wash Pipe 13. Explosion-proof Light 14. Water Outlet Pipe |