Get in touch with us

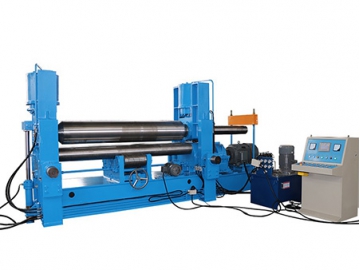

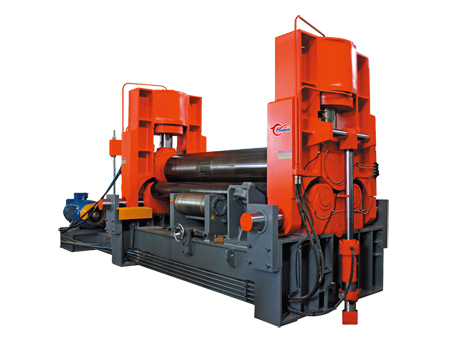

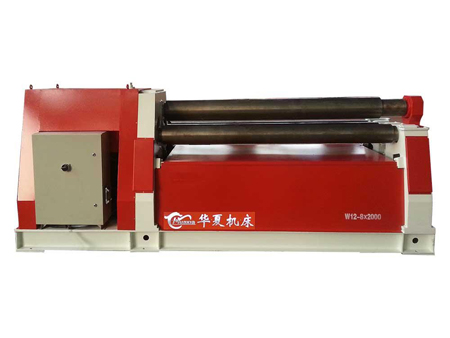

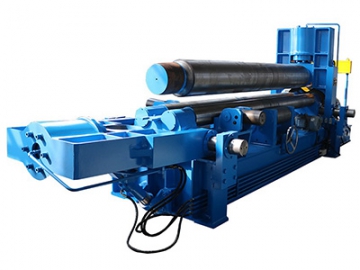

Universal Plate Bending Machine

Universal plate bending machine is suited to roll various materials including carbon steel and low alloy steel under normal temperature. It is capable of pre-bending of both ends of the material plate at one time, as well as performing the processes of rolling and leveling of metal plate.

The upper roller can realize vertical and horizontal movements. Pre-bending operation can be implemented through horizontal motion of upper roller, while the lower roller remains the same height to facilitate feeding and operation.

Features

- SIEMENS industrial touch screen is adopted, and coupled with PLC to achieve optimal efficiency.

- All electrical parts are from SIEMENS such as current relay and air switch to guarantee safe operation.

- Hydraulic components are from Japan YUKEN.

- The plate bending machine features smooth operation, flexible control, without abnormities such as jamming, oil leakage and irregular noise.

- Tilting frame is hydraulically operated, providing fast running and high efficiency.

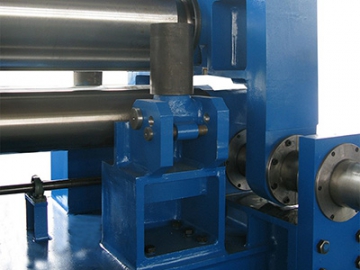

- Upper roller adopts hydraulic transmission for vertical movement and mechanical transmission for horizontal movement.

- There is a safe protection function when upper roller is lifted to the limit position.

- Tilting and resetting of tilting cylinder is protected by limit switch.

- Control unit has an emergency stop button to enable the machine to be stopped immediately, allowing operator to stop the operation when any failure occurs, thus to protect the safety of both operator and equipment.

Applications

Details

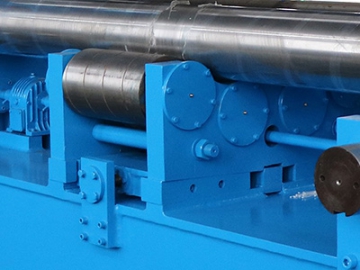

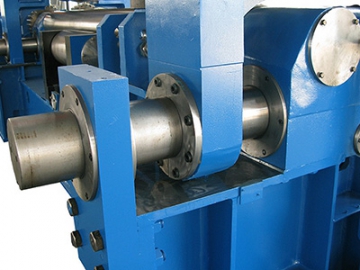

Transmission unit

Transmission unit  Work roll

Work roll  Support roll

Support roll  Hydraulic system

Hydraulic system  Electric system

Electric system  Hydraulic tilting system

Hydraulic tilting system  Remote control

Remote control  Guide rail for upper roller horizontal movement

Guide rail for upper roller horizontal movement

Optional configurations

Cone rolling unit

Cone rolling unit  Cooling system

Cooling system  Side support

Side support  Upper support

Upper support

Specifications

| W11s | |||||

| Specification | Rolling thickness(mm) | Pre-bending thickness(mm) | Rolling Width(mm) | Diameter of upper roller(mm) | Main power(Kw) |

| W11SNC-12x2000 | 12 | 10 | 2000 | 250 | 5.5 |

| W11SNC-16x2000 | 16 | 12 | 2000 | 255 | 7.5 |

| W11SNC-16x2500 | 16 | 12 | 2500 | 300 | 15 |

| W11SNC-20X3000 | 20 | 16 | 3000 | 375 | 18.5 |

| W11SNC-25X2500 | 25 | 20 | 2500 | 380 | 22 |

| W11SNC-30X2500 | 30 | 25 | 2500 | 410 | 30 |

| W11SNC-30X3000 | 30 | 25 | 3000 | 450 | 37 |

| W11SNC-35X2500 | 35 | 30 | 2500 | 460 | 37 |

| W11SNC-35X3000 | 35 | 30 | 3000 | 510 | 45 |

| W11SNC-40X2500 | 40 | 35 | 2500 | 500 | 45 |

| W11SNC-40X3000 | 40 | 35 | 3000 | 540 | 45 |

| W11SNC-40X4000 | 40 | 32 | 4000 | 610 | 55 |

| W11SNC-45X3000 | 45 | 40 | 3000 | 590 | 55 |

| W11SNC-50X4000 | 50 | 45 | 4000 | 700 | 55 |

| W11SNC-55X3000 | 55 | 45 | 3000 | 620 | 55 |

| W11SNC-60X3000 | 60 | 55 | 3000 | 650 | 75 |

| W11SNC-60X4000 | 60 | 50 | 4000 | 780 | 75 |

| W11SNC-70X3000 | 70 | 60 | 3000 | 710 | 90 |

| W11SNC-75X3000 | 75 | 65 | 3000 | 740 | 90 |

| W11SNC-80X3000 | 80 | 75 | 3000 | 760 | 60 |

| W11SNC-80X4000 | 80 | 70 | 4000 | 860 | 90 |

| W11SNC-90X4000 | 90 | 80 | 4000 | 790 | 110 |

| W11SNC-100x3000 | 100 | 90 | 3000 | 820 | 110 |

| W11SNC-120X3000 | 120 | 100 | 3000 | 860 | 110 |

| W11SNC-160x3000 | 160 | 120 | 3000 | 1080 | 2x75 |

Related products

Send Message

Most Recent

More

Other Products

Videos