Get in touch with us

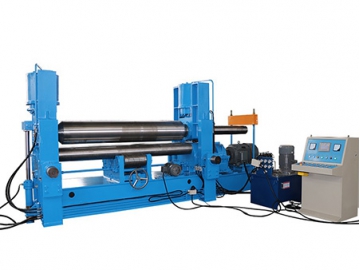

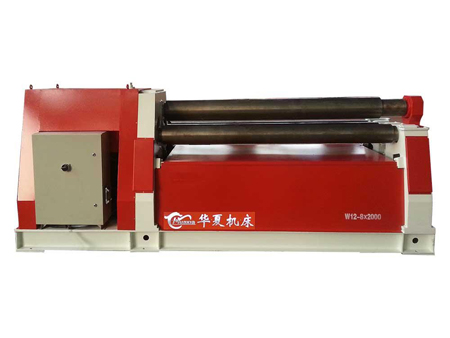

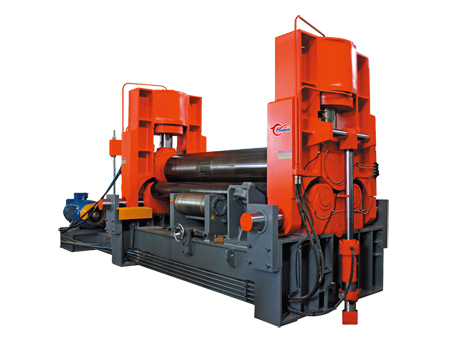

Variable-axis Plate Bending Machine

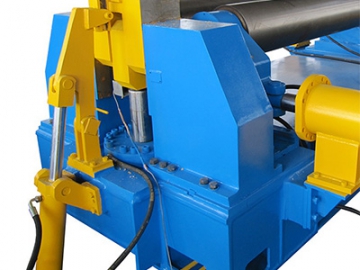

Variable-axis plate bending machine has three rolls that move independently, the upper roller does vertical movement while the two lower rollers move horizontally. The center distance between the lower rollers and the distance between the pre-bending points can be adjusted according to the thickness of metal plate, thus providing optimal rolling capacity.

The center distance between the two lower rollers can be increased through the horizontal movement of the two lower rollers, the upper roller moves downward similar to a press brake to minimize the length of the straight edge, thus offering a better pre-bending quality. The 3-roll variable-axis plate bending machine is an ideal economical alternative to 4-roll plate bending machine which provides the same performance.

- Three rolls are forged and hardened, the hardness reaches HRC48-55, which are featured by high strength, good wear resistance, and suitable for heavy workload operation.

- Double row roller bearings are used to support work rolls, ensuring a low friction coefficient while reducing reactive power loss.

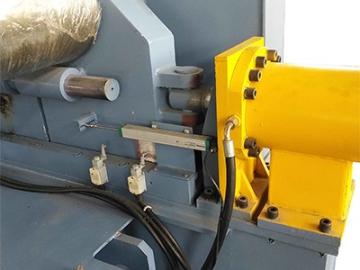

- Tilting and resetting of bearing body are designed with interlocking device to provide safe operation.

- Main electric parts are from Siemens and Schneider, featuring long service life and maintenance free operation.

- Moveable control console is easy to operate, touch screen shows the precise positions of three rolls.

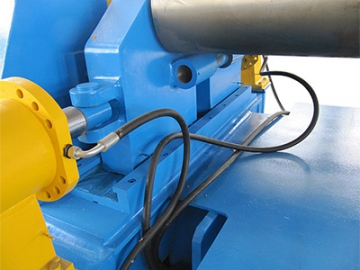

- Hydraulic system is outfitted with high grade valves which feature large flow rate, low resistance and low heat, enabling the machine to be highly reliable.

- Hydraulic pipeline connector has reliable radial seal, guaranteeing the smooth operation of hydraulic system without oil leakage.

- Hydraulic system has oil filter to keep the system clean.

- Machine base is an integral structure, robust and easy to assembly. Both machine body and base are annealed for eliminating of internal stress and improving of processing accuracy.

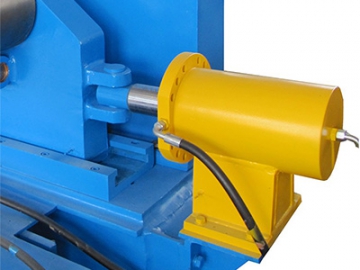

Hydraulic cylinder

Hydraulic cylinder  Support of horizontal movement

Support of horizontal movement  Hydraulic tilting system

Hydraulic tilting system  Linear encoder

Linear encoder  Hydraulic motor

Hydraulic motor  Control system

Control system  Hydraulic system

Hydraulic system  Remote control

Remote control

Cooling system

Cooling system  Upper support

Upper support