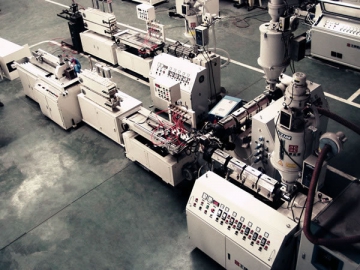

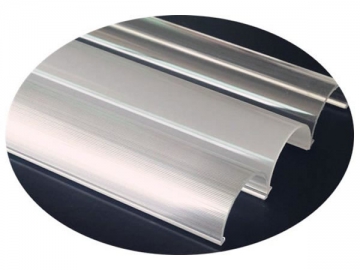

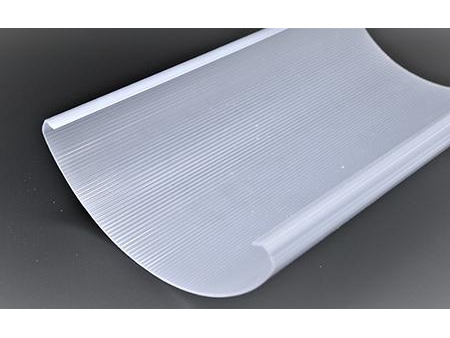

PC,PMMA,PS lampshade extrusion line

PC Lampshade Extrusion Line / Lampshade Extrusion Line / Energy Saving Lampshade Extrusion Line

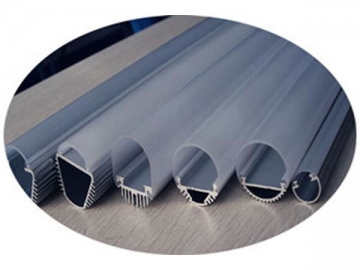

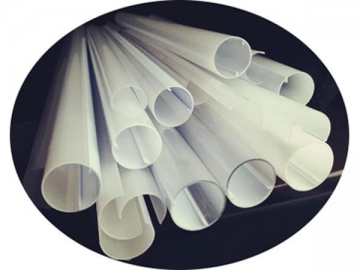

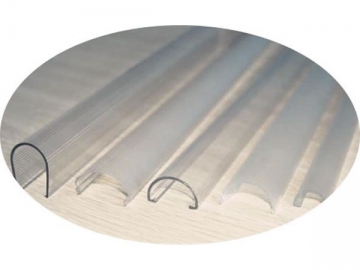

The PC/PMMA/PS lampshade extrusion line is used to produce PS/PMMA transparent, semi-transparent, PC-LED energy saving lampshades and fluorescent tube profiles widely used in the illumination and decoration industries. The primary raw materials include PS and engineering plastic (PC/PMMA).

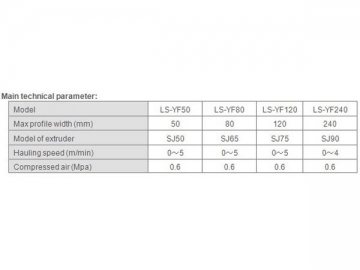

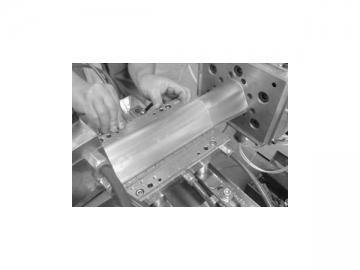

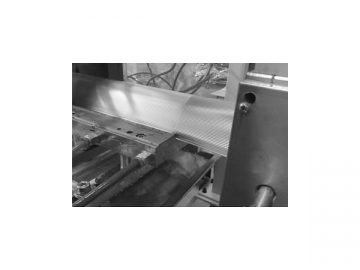

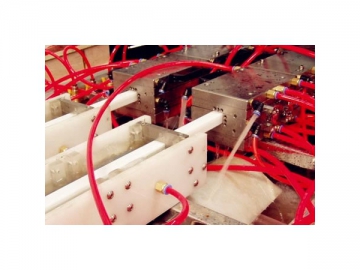

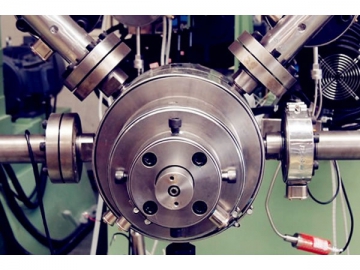

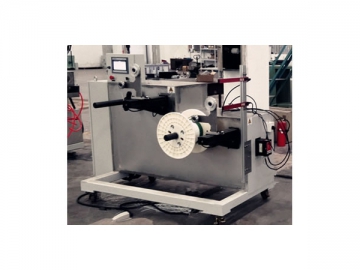

The lampshade extrusion production line includes a highly efficient single screw extruder, calibration table, haul off and precise cutter. The screw and barrel utilize Japanese technology designed specifically for PC/PMMA material processes. The profile calibrator is made from imported steel, and the precise processing ensures an exact and stable profile size, while the ball screw cutting type ensures the cutting precision is /-1.0mm.

The cutter uses a professionally designed saw blade controlled by a PLC system for a smooth, flat cut.

The optimized length counter and dust collector configuration ensure a high performance profile extrusion line.

PC LED Lampshade extrusion:

PMMA Lampshade extrusion: