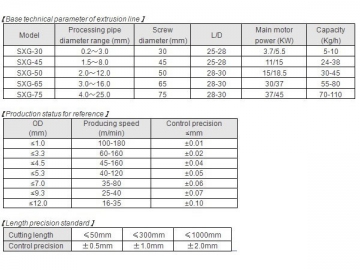

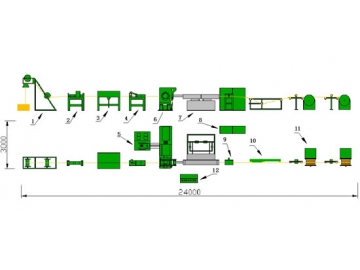

Precision medical tube extrusion line

Medical Tube Extrusion Line / Precision Tube Extrusion Line / Medical Catheter Extrusion Line

Introduction

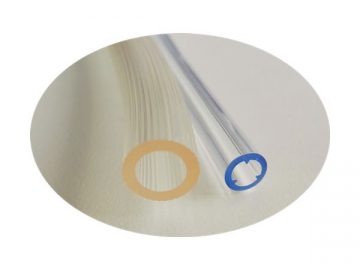

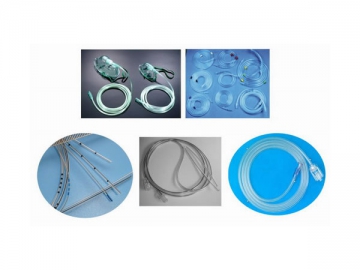

A medical tube extrusion line is used to produce various types of medical catheters, including perfusion tubes, urethral catheters, central venous catheters, capillary tubes, stomach tubes, multi-hole tubes and other medical tubes.

The precision medical tube extrusion line is one of the products in the SXG series precision tube extrusion line. With an accurate control of the weak vacuum, and a high pressure volumetric extrusion forming technology, the medical tube extrusion line is known for its extraordinary extrusion speed (maximum 180m/minute), high extrusion stability and extreme control accuracy of the tube sizes (CPK value ≥ 1.6).

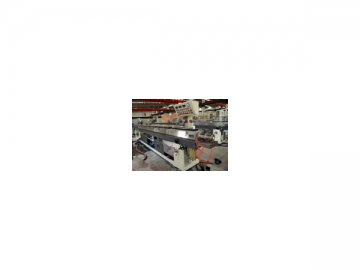

-

Extruder

Extruder -

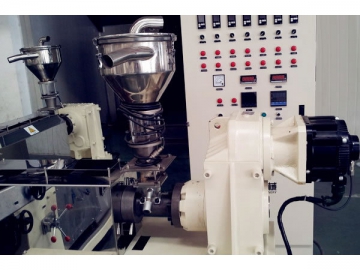

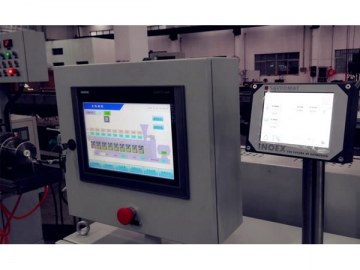

HMI panel

HMI panel

Equipment Features

Optimum screw and driving system design, with an excellent extrusion and plasticization effect:

The core rods are made of S136 mold steel material, which ensures the inner flow surface glossiness and corrosion resistance. The mold structure uses high pressure volumetrics, designed in house, in order to provide a stable and high speed extrusion for the tube material with tiny fluctuations.

With the use of accurate control of the weak vacuum technology, the vacuum and water system are separately controlled. By doing so, we can coordinate the multilevel water balance control system with the vacuum system, ensure a stable vacuum degree, cool the water levels and water flowage.

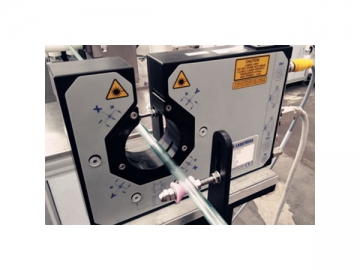

This extrusion machine also uses a BETA/Proton LaserMike bi-direction high speed diameter measurement system to measure the diameter online, with a measuring precision to within 0.001mm.

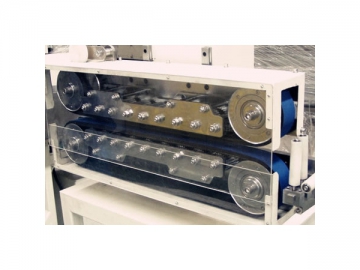

The puller uses an imported multi-layer composite wearable strap that meets medical sanitary requirements. It is a high level precision roller, and the servo motor drive offers a high stability pulling performance.

The cutter is equipped with a low inertia aluminum alloy rotating knife arm structure, which is driven and controlled by a Servo system that offers a high speed and highly accurate cutting action. With a Mitsubishi PLC programmable control and SIEMENS human to computer interface, the cutter can achieve continuous cutting, timing of the cutting length count for cutting and other functions. The cutting length can be freely set, and counting is done automatically.

-

Die

Die -

Vacuum sizing tank

Vacuum sizing tank -

Laser gauge

Laser gauge

-

Puller

Puller -

Cutter

Cutter -

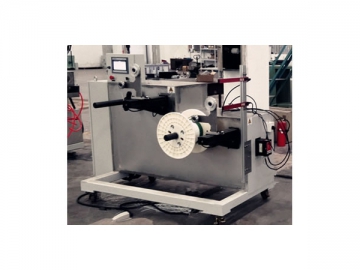

Winding machine

Winding machine

After years of research, improvements and expansion of the medical tube extrusion equipment, we have established a great market foundation, and have supplied machines to internationally known medical product companies all over the world, including Fresenius Medical Care, GAMBRO Medical Products, NIPRO CORPORATION, Meditech System, BJD Medical, WEGO Group, TERUMO Corporation, Epic International, and ITL Healthcare.

Case show:

End-user: Fresenius Medical Care

Project start date: 2007

Machine line: SPVC high speed tube EXTRUSION LINE SXG-75T, SXG-80T, SXG-100T

Machine line quantity: 5 lines

Capacity: average 90-160KG/h