Get in touch with us

Four Rollers Plate Bending Machine

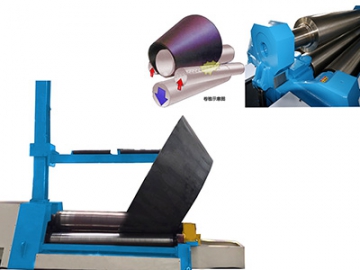

The 4 rolls plate bending machine is hydraulically operated, PLC programmable and controlled by numerical control system, capable of accomplishing automatic rolling process.

During the plate rolling process, top roll stays the same position and the bottom roll moves vertically to hold the metal plate tightly against the top roll. At the same time, two side rolls do the upward movement by linear guide to adjust curvature radius of bent plate, which can implement pre-bending at the end and bending processes in a single direction and in one pass. Automatic mode can be applied in mass production, it provides high forming consistency for workpieces from the same batch.

Features

- The plate bending machine can be precisely controlled by NC and CNC numerical control systems, suited to be used in mass production.

- Four rolls are forged and hardened, the hardness reaches HRC48-55, which are featured by high strength, good wear resistance, and suitable for heavy workload operation.

- Double row roller bearings are used to support work rolls, ensuring a low friction coefficient while reducing reactive power loss.

- Side rolls can be raised for accurate pre-bending.

- The bottom roll and side rolls can be tilted for cone rolling.

- The movements of bottom roll and side rolls are controlled by computer, achieving automatic alignment. Digital display of touch screen provides easy operation, synchronization accuracy reaches ±0.1mm.

- Tilting and resetting of bearing body are designed with interlocking device to provide safe operation.

- Main electric parts are from Siemens and Schneider, featuring long service life and maintenance free operation.

- Moveable control console is easy to operate, touch screen shows the precise positions of work rolls.

- The plate bending machine adopts PLC programmable control system, which has functions of fault diagnosis, machine parts monitoring, as well as data memory function when power is goes off.

- Hydraulic system is outfitted with high grade valves which feature large flow rate, low resistance and low heat, enabling the machine to be highly reliable.

- Hydraulic pipeline connector has reliable radial seal, guaranteeing the smooth operation of hydraulic system without oil leakage.

- Hydraulic system has oil filter to keep the system clean.

- Machine base is an integral structure, robust and easy to assembly. Both machine body and base are annealed for eliminating of internal stress and improving of processing accuracy.

Applications

Details

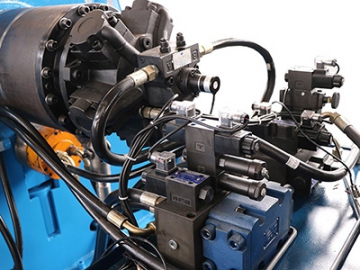

Hydraulic motor

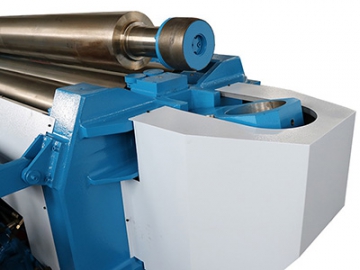

Hydraulic motor  Heavy duty work rolls

Heavy duty work rolls  Hydraulic tilting system

Hydraulic tilting system  Lifting cylinder

Lifting cylinder  Control console

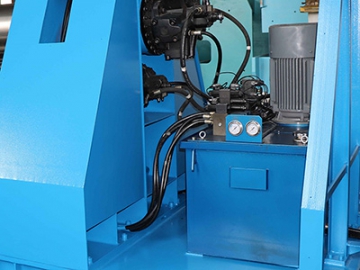

Control console  Hydraulic system

Hydraulic system  Electric system

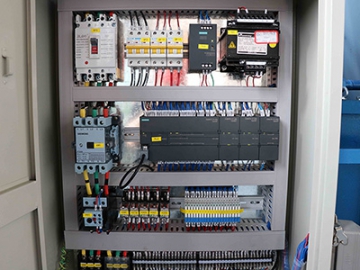

Electric system  Siemens touch screen

Siemens touch screen

Optional configurations

Cone rolling unit

Cone rolling unit  Side support / Upper support

Side support / Upper support  Cooling system

Cooling system  Feeding system

Feeding system

Specifications

| 8*1500 | 8*2500 | 10*3000 | 12*2500 | 12*3000 | 16*2500 | 16*3000 | 20*2500 | 20*3000 | 25*2500 | 30*3000 | 25*3000 | 30*2500 | 40*2500 | 40*3000 | 50*2500 | 60*3000 | |||

| Max. | Thickness of bending plate | (mm) | 8 | 8 | 10 | 12 | 12 | 16 | 16 | 20 | 20 | 25 | 30 | 25 | 30 | 40 | 40 | 50 | 60 |

| Thickness of pre-bending | 6 | 6 | 8 | 10 | 10 | 12 | 12 | 16 | 16 | 20 | 25 | 20 | 25 | 32 | 32 | 40 | 50 | ||

| Width of bending plate | 1500 | 2500 | 3000 | 2500 | 3000 | 2500 | 3000 | 2500 | 3000 | 2500 | 3000 | 3000 | 2500 | 2500 | 3000 | 2500 | 3000 | ||

| Effective length of the rollers | (mm) | 1550 | 2550 | 3050 | 2550 | 3050 | 2550 | 3050 | 2550 | 3050 | 2550 | 3100 | 3050 | 2600 | 2600 | 3100 | 2600 | 3050 | |

| Yield strength of plate | (MPa) | 235 | 235 | 235 | 235 | 235 | 235 | 235 | 235 | 235 | 235 | 235 | 235 | 235 | 235 | 235 | 235 | 235 | |

| Min. reel dia. with max. size | (mm) | 400 | 500 | 550 | 550 | 700 | 600 | 700 | 600 | 800 | 700 | 800 | 800 | 800 | 1100 | 1000 | 1200 | 1800 | |

| Diameter of roller | Upper | (mm) | 180 | 250 | 300 | 280 | 360 | 300 | 350 | 350 | 400 | 400 | 460 | 420 | 450 | 520 | 560 | 620 | 680 |

| Bottom | 170 | 230 | 280 | 260 | 340 | 280 | 330 | 320 | 380 | 380 | 440 | 400 | 410 | 480 | 550 | 600 | 660 | ||

| Side | 150 | 200 | 240 | 220 | 260 | 230 | 260 | 280 | 280 | 320 | 380 | 340 | 360 | 420 | 460 | 500 | 520 | ||

| Roller | Material | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | 42CrMo | |

| Hardness | (HB) | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | 240-286 | |

| Induction hardened roll | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES | YES | ||

| Roll Profile | crown | crown | crown | crown | crown | crown | crown | crown | crown | crown | crown | crown | crown | crown | crown | crown | crown | ||

| Lifting mode | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | ||

| Lifting synchronous precise | ±(mm) | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | |

| All bearing brands | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | Self aligning roller bearing | ||

| Conical bending device | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||

| Driving mode | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | Motor reducer | ||

| Control system | Control mode | NC | NC | NC | NC | NC | NC | NC | NC | NC | NC | NC | NC | NC | NC | NC | NC | NC | |

| Display of position & displacement | LCD | LCD | LCD | LCD | LCD | LCD | LCD | LCD | LCD | LCD | LCD | LCD | LCD | LCD | LCD | LCD | LCD | ||

| PLC | Omron | Omron | Omron | Omron | Omron | Omron | Omron | Omron | Omron | Omron | Omron | Omron | Omron | Omron | Omron | Omron | Omron | ||

| Electrical part system | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | Siemnens | ||

| Plate bending speed | (m/min) | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | About 3.5 | |

| Descending/ascending speed of bottom roller | (mm/min) | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | About 160 | |

| Descending/ascending speed of side roller | (mm/min) | About 260 | About 260 | About 260 | About 260 | About 260 | About 260 | About 260 | About 260 | About 260 | About 260 | About 260 | About 260 | About 300 | About 300 | About 300 | About 300 | About 260 | |

| Main power motor | (KW) | 5,5 | 7.5 | 11 | 11 | 18.5 | 11 | 18.5 | 18.5 | 18.5 | 22 | 30 | 22 | 30 | 18.5*3 | 2*22 | 55 | 55 | |

| Hydraulic system | Max. working pressure | (MPa) | 25 | 22 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 25 |

| Valve | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | Yuken | ||

| Seal | Valque | Valque | Valque | Valque | Valque | Valque | Valque | Valque | Valque | Valque | Valque | Valque | Valque | Valque | Valque | Valque | Valque | ||

| Electrical & hydraulic protection against overload | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | ||

| Construction steel material | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | Q235 | ||

| Side support for big sheet metal diameters | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | ||

| Central support for big sheet metal diameters | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | ||

| Feeding table | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | ||

| Oil cooler system | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | optional | ||

Related products

Send Message

Most Recent

More

Other Products

Videos