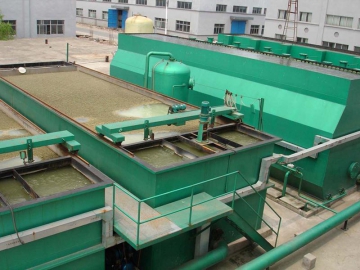

Cavitation Air Flotation System

The content of suspended solids inflow of the cavitation air flotation system is usually no more than 1000 mg/L, and will not exceed 2000 mg/L. After purification, the content of suspended solids in water can be below 20 mg/L.

The cavitation air flotation system is not only applied in the pretreatment of paper making waste water, petroleum waste water, chemical industry waste water, textile printing waste water, leather waste water, electroplating waste water, starch waste water, hospital waste water, pharmacy waste water, brewing waste water, coating waste water, dairy product processing waste water and urban waste water, but also can be used in advanced biochemical treatment applications.

The feature of the cavitation air flotation system

(1) Cost minimization: The cavitation air flotation system does not need to be equipped with a pressure container, air compressor or circulating pump, minimizing operation cost. The occupied space of the machine is small and decreases the civil engineering investment.

(2) Low power consumption and low operation cost.

(3) High efficiency of treatment: The removal rate of the petroleum and suspended solids (SS) is over 80%. And the removal rate of BOD and COD can exceed 30%.

(4) Operating easily: automatic control

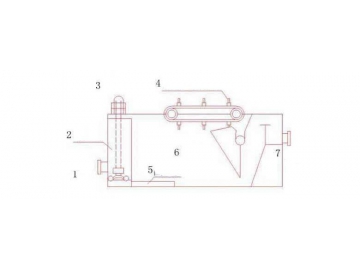

Design principle

The cavitation air flotation system is specially designed to remove grease, jelly and suspended solids (SS) of industrial sewage and urban sewage. The cavitation air flotation system includes five parts.

1. Water inlet

2. Aeration process

3. Aeration machine

4. Chained sludge scraping system

5. Return pipe

6. Air flotation groove

7. Water outlet

The sewage flows into the small scale air inflation pipe equipped with the cavitation aeration machine. The sewage flows through the air inflation pipe in the rising process and mixes completely with the micro bubble which produced by the aeration machine. The aeration machine creates a vacuum space in the water, while the gas diffusion impeller is in the bottom of the air transmission pipe has a high speed rotary movement. The air in the water surface flows through the aeration machine into the water to fill up the vacuum space, then it will create micro bubbles and spirally rise to the water surface.

The suspended solids in the water whose density is over 1 will be subsided and separated naturally due to gravity. While the suspended particles whose density is almost equal to 1, hardly to subside or float will be adhered by many scattered micro bubbles in water and these suspended particles will rise to the water surface and be separated along with the bubbles. The floating process needs the flotation agent. The flotation agent not only can change the hydrophilia of suspended solids, but also can promote the bubble formation.

The suspended solids rise along with the micro bubbles to the water surface and form the bubble layer, and the sludge scraping machine which moves along the water surface scrapes the bubbles and sends them to the metal plate, then expels them.

Customization notice of the cavitation air flotation system

Please provide the water quality parameters and water treatment quantity. If you cannot provide the water quality parameters, please provide the kind of sewage in your system and we can customize the air flotation system as needed.

Huaneng Jinhao manufactures water treatment equipment and domestic sewage treatment plant to global markets, with decades of experience, we can fabricate any water treatment equipment and machinery like industrial water decanter, water filtration equipment, sludge separation equipment, and the auxiliaries of water treatment equipment.

Index

wastewater treatment, sewage treatment, industrial DAF system