Synchronized Tandem Press Brake

Bending Machine/ Hydraulic Press/ Press Brake

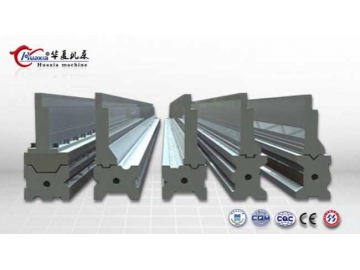

Description of Synchronized Tandem Press Brake

The tandem press brake machine is the main machine in light pole forming.

Features of Synchronized Tandem Press Brake

The frame of the machine is composed of a cylinder, worktable, left and right housings and a ram.

Electric-hydraulic proportional valve to ensure the synchronization of both machines.

High quality position measuring system, guide and hydraulic balance system to maximize precision and efficiency.

| Model | 2-WE67K-400/6000/7000 | |

| Machine structure | Tandem hydraulic CNC electro-hydraulic synchronized machine. | |

| Working force | 2X400Ton | |

| Length of table | 2X6000mm/7000 | |

| Distance between frames | 5600mm | |

| Throat depth | 950mm | |

| Open height | 1050mm | |

| Stroke | 320mm | |

| Working Speed | Unload | 70mm/s |

| Working | 7mm/s | |

| Return | 60mm/s | |

| Main motor | 2x30kw | |

| CNC system | Type: DELEM DA52 Delem Co., Netherlands 2 (Y1,Y2) | |

| Tool | With 1 punching and 1 multi V block bottom die for making min 60mm OD octagonal taper type light pole. The up tool holder thickness is 18mm The working table with mechanical type crowning system, With front and back sheet supporting stand | |

| Seal in the cylinders | NOK, made in Japan | |

| Hydraulic components | BOSCH-Rexroth - , Germany | |

| Hydraulic pump | Nitch, Japan, or BOSCH , Germany, | |

| Linear raster displayer sensor | Heidenhain , Germany | |

| Main electric elements in cabinet | Schneider | |

| Gross weight | 124000 kg | |

| Overall size (mm) LxWxH | 2x7250x5170x5970 | |

| Packing | With plastic cover The machine should be disassemble prior to transportation. Our engineers can visit the customer to assemble and adjust it. | |

Related products

Send Message

Most Recent

More

Other Products

Videos