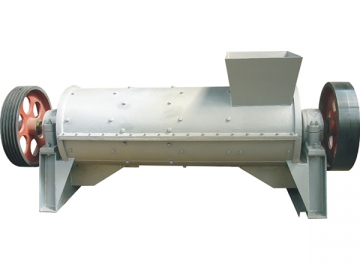

Coarse Refiner

Capacity: 10-30 T/D

The ZSM series coarse refiner is a great choice for the coarse grinding of pulp raw materials and re-pulping of broke and waste paper. This paper mill equipment is also suitable for the refining of continuous fiber pulps such as cotton pulp, wood pulp and helm pulp.

Features of the Coarse Refiner

1. The pulp equipment comes with a long refining zone and strong cutting capacity for fiber.

2. It ensures less damage to the fiber capillary, and a homogenous refining result. The materials will be ground roughly before entering the defibering zone, thus ensuring the paper has a high fracture length, tearing strength, and breaking strength.

3. The conical refiner features a low energy consumption, high production capacity high efficiency, low noise and easy maintenance.

4. It is equipped with both manual and electric operating devices.

| Model | ||

| Rotor diameter (mm) | Φ250 | Φ350 |

| Pulp consistency (%) | 30-90 | 30-90 |

| Speed (r/min) | 720 | 720 |

| Capacity (t/d) | 10-15 | 15-30 |

| Motor power (Kw) 6 Grade | 30-37 | 45-55 |

| Weight (kg) | 1280 | 2200 |

This high efficiency coarse refiner is mainly used for the pulping process without chemicals. It is not only suitable for the coarse grinding of straw, bagasse, reeds, wood chips, cotton stalks, wood shavings, saw dust, knot pulp, waste flax and more, but it can also be applied to the grinding of raw materials naturally fermented or steeped by lime water.

For coarse grinding after digestion, the pulp materials have been sufficiently defiberized can easily absorb the chemicals, thus reducing the digestion time without requiring any chemicals. After being processed in the coarse refiner, the materials need only be refined in a pulp refiner, and can then be delivered to the paper machine

Product Showcase