Vacuum Coating Machine (with Medium-frequency Magnetron Sputtering)

The cathode may be any of metals, including copper, titanium, nickel, and chromium. In some cases, the free metal ions react with the ionized gas (i.e. nitrogen) contained in the plasma environment to form a metal compound for coating, such as titanium nitride, titanium carbide, and zirconium nitride.

Arc vaporization uses a cathode as the source of deposition. Therefore, the process is also known as cathodic arc vaporization, or cathodic arc plasma deposition. Highlighted on this page is the vacuum coating machine that can conduct the arc vaporization process and has found wide use in metatallizing watches, door locks, crockery, kitchenware, eyeglass frames, luminaire, bathroom fixtures and more.

As a specialized vacuum coating machine provider, we can customize your vacuum coater or vacuum metallizer to suit your specific coating requirements.

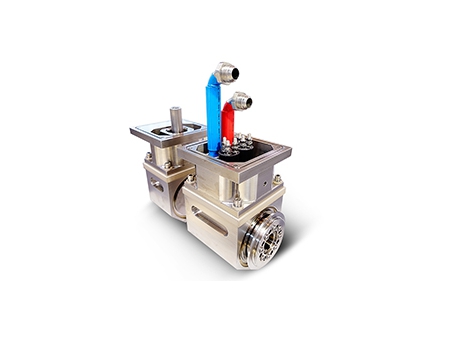

Medium frequency pulsed magnetron sputtering is a physical vapor deposition process that combines pulsed power technology, magnetron sputtering deposition, and arc evaporation into one operation. This PVD technology improves coating performance and allows metals, metal compounds and multi-layer films to be deposited on the surface of various metal and non-metal tools and parts.

With years of dedicated experience in the research and development of vacuum coating technology, our team of technicians uses cathodic arc sources to supply free ions, and an unbalanced magnetic field to confine the plasma to an area near the target but not reaching the target. Advanced computer system maintains overall, automatic control of the system. The resulting film of coating is dense, sticks tightly to the substrate, and has uniform thickness across the substrate surface.

Applications of Vacuum Coating Machine

Coats metals, metal compounds or other materials onto watches, cellphone cases, metal hardware, sanitary ware, kitchenware, and wear-resistance tools, molds and dies.

Material to Be Deposited

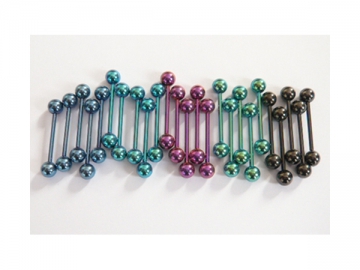

This vacuum coating machine is quite a multi-tasker, as it applies Tin, TiCN, CrN, TiALN, TiCrN, ZrN, or TiNC to the substrate surface.

Colors of Coating

BITE vacuum coater can create a variety of colors, including black, rainbow (5 colors), rose gold, among other colors.

Features of Vacuum Coating Machine

1. Magnetron sputtering technology utilizes a magnetic field that extends from the target material to near the substrate surface. As the target atoms are energized, they are directed towards the substrate under the magnetic force. A high degree of target ionization can be achieved, along with an exquisite powder coating and excellent surface finish.

2. Cathodic arc plasma deposition generates a stable plasma using an optimized cathode that operates with 30A electric current. The coating layer bonds tightly to the substrate partly due to the atomic diffusion process.

| Model | ||||

| Vacuum Chamber Size | ф900×1000 | ф1100×1200 | ф1250×1100 | ф1350×1100 |

| Vacuum Pump Speed | 1×105 Pa~3×10-3 Pa≤20min | |||

| Maximum Vacuum Level | ≤1×10-3 Pa | |||

| Auxiliary Equipment | 2x-15 /2x-70 /ZJP-300 /KT-600 Options F-400/3600 molecular pump | 2x-15 /2x-70 /ZJP-300 /KT-630 Options F-400/3600 molecular pump | 2x-15 /2x-70 /ZJP-300 /KT-630 Options F-400/3600 molecular pump | 2x-15 /2x-70 /ZJP-300 /KT-630 Options F-400/3600 molecular pump |

| Transmission | Planetary Gear (number of shafts: 8-16, as per customer requirements) | |||

| Heating Method | Heating tubes are on mounted to the side of the vacuum chamber | |||

| Ion Bombardment | Pulse voltage: 0-1000V (available with a voltage converter) | |||

| Gas Supply | Automatic glow control valve ensures a steady supply of gas into the vacuum chamber. | |||

| No. of Cathodic Arcs | 6 arcs | 6-8 arcs | 8-10 arcs | 8-12 arcs |

| Magnetically Controlled Targets | 1-2 (Flat or cylindrical targets are available.) | 2-4 (Flat or cylindrical targets are available.) | 2-8 (Flat or cylindrical targets are available.) | 2-8 (Flat or cylindrical targets are available.) |

| Working Method | Semi-automatic PLC or fully automatic PC PLC | |||

| Gas Environment | Ar , N2, O2, C2H2 | |||

| Total Power | 40KW | 45-60KW | 60-80KW | 70-90KW |

| Compressed Air Pressure | 0.4~0.8MPa | |||

| Water Cooling System | Water pressure/temperature: ≤25 ℃ /≥0.25MPa (Currently unavailable) | |||

Vacuum Coating Samples

.jpg)