Hydrogen Gas Cutting Systems

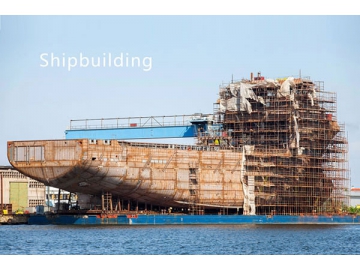

This hydrogen gas cutting system was developed to cut through steel using high temperature flames fueled by hydrogen gas generated by water electrolysis. The system provides high cutting speed, smooth cutting surfaces, and good verticality of the cutting edge. The hydrogen gas cutting system consists of an oxygen-hydrogen generator and cutting equipment. The cutting component can be a manual torch, semi-automatic linear cutting machine, or CNC cutting machine.

Advantages of the hydrogen gas cutting system- Environmentally friendly: It creates hydrogen and oxygen through electrolysis of water and cuts the material with high temperature flames fueled by clean burning oxyhydrogen gas to eliminate CO2 emissions.

- High cutting speed: The concentrated oxyhydrogen flame features fast burning speed that ensures high cutting speed and a short preheating time.

- Excellent cutting effect: Products will feature a smooth cutting surface and no obvious welding slag.

| Model | Kingkar5800cw | Kingkar7800cw |

| Maximum cutting thickness | 100mm | 150mm |

| Effective punching depth | 90mm | 120mm |

| Cutting Material | soft steel, medium carbon steelhigh manganese steel | |

| Maximum water consumption | 2.42/H | 3.2L/H |

| Voltage | 380V three phase power | 380V three phase power |

| Power source frequency | 50/60 Hz | 50/60 Hz |

| Maximum hydrogen production rate | 5800L/Hr | 7800L/Hr |

| Maximum working pressure | 0.2 Mpa | 0.2 Mpa |

| Dimensions (L´W´H) | 1300*930*1560mm | 1300*930*1720mm |

| Net weight | 365kg | 500kg |

Related products

Send Message

Most Recent

More

Other Products

Videos