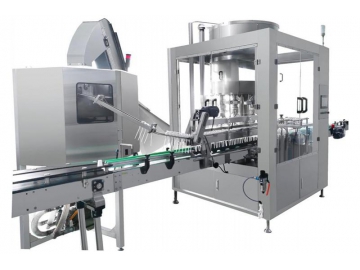

Spindle Capper for Spray Pump

Request a Quote

Application:

The ZHX200 inline capping machine uses a screw capping system where the operator can adjust the capping speeds for a different yield. It features efficient operation, and can be paired with high speed capping machines to form a bottle packaging line. The inline capping machine is widely used for medical and pharmaceutical packaging, cosmetic packaging, food packaging and more.

Parameter:

Power supply: AC220V; 50Hz

Power: 1.5kw

Weight: about 680kg

| Num. | Item | Description |

| 01 | Outer dimension (Length ×Width ×Height) | 2000mm*1790mm*2900mm |

| 02 | Weight | 4500Kg |

| 03 | Cap size | 35-40mm (Diameter) |

| 04 | Quantities of capping head | 8 |

| 05 | Capacity | 5000pcs/h (steadily ) |

| 06 | Torsion | ±0.3Nm |

| 07 | Capping error | ≤0.5% |

| 08 | Power | AC 380V,50Hz |

| 09 | Total power | 4Kw |

| 10 | Air pressure | 0.6Mpa (clean and stable) |

- The spindle capper for spray pumps is designed with eight manipulators for automatic bottle feeding, arranging the mass bottles, gripping and capping. The capping machine has a high production efficiency of 5,000 bottles/hour.

- The capping machine is designed with a failure protection function, so that it sorts out any bottles with no caps, and no soft tubes.

- This capper can be matched with filling machines and labeling machines to form an automatic packaging line.

- Our capping machine can be used for capping the containers produced using PE, PP and HDPE materials.