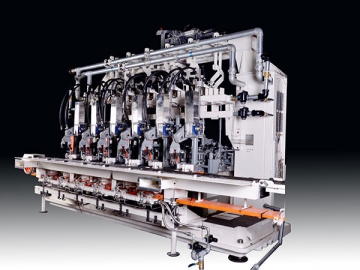

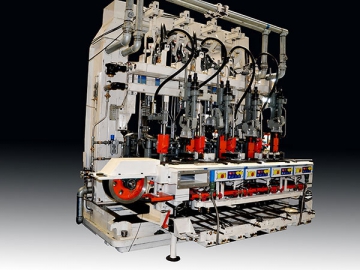

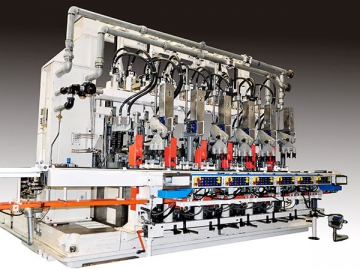

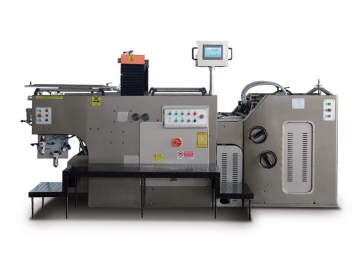

Double Gob IS Machine, HS4.6.8.10-108

Request a Quote

Configurations of the Double Gob Individual Section Machine

Glass Container Specifications

Consumptions of the Individual Section Machine

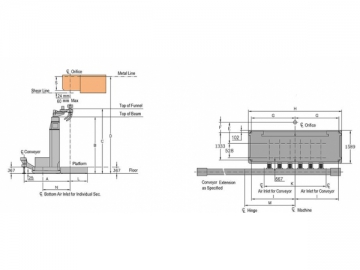

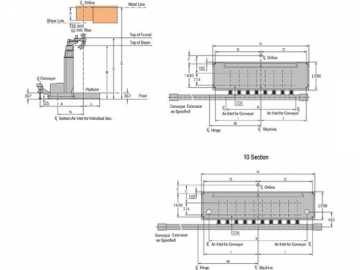

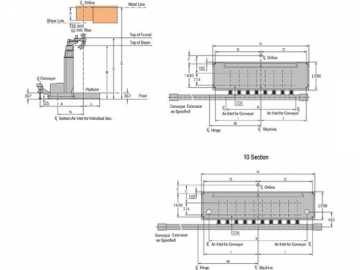

Installation Dimension of the Glass Container Forming Machine

Installation Dimension of the Glass Container Forming Machine

| FLEXLINE Control System | |

| Servo Gob Distributor with Funnel Guide | |

| Delivery Suspension System, Air Pad Scoops | |

| Linkages in Oil System for Blank and Blow Molds | |

| Blank Mold with Protecting Brackets | |

| Constant Cushion Invert Mechanism | Optional |

| Servo Electric Invert Mechanism | |

| VertiFlow Blow Mold Cooling Mechanism | |

| Bottom Plate Mechanism with Vacuum-Assistant Forming | Optional |

| Quick Change Plunger Mechanism | |

| Constant Cushion Take-out Mechanism | Optional |

| Servo Electric Take-out Mechanism | |

| Quick Change Takeout Tong | |

| Wide Uprights for Machine | |

| 26# Electro-Pneumatic Valve Block (EPVB) | |

| Conveyor with Silent Chain | |

| Electronic Pusher, Double Axes | |

| On/off Control Blank Mold Cooling Mechanism | Optional |

| Timing and Rationing Automatic Lubrication System | |

| Process Change from Double Gob to Triple Gob (159) | |

| Glass Container Forming Methods | |

| Blow and Blow | |

| Press and Blow | |

| Narrow Neck Press and Blow | |

| Blow and Blow | Press and Blow | Narrow Neck Press and Blow | ||

| Ware Range | ||||

| Maximum Body Diameter with VertiFlow | 76mm | |||

| Maximum Body Diameter (Stack Cooling without Vacuum) | 90mm | |||

| Maximum Body Diameter with Vacuum | 76mm | |||

| Minimum Height under Finish | 105mm | 86mm | ||

| Maximum Height under Finish (with VertiFlow) | 287mm | 268mm | ||

| Maximum Finish Diameter | 48mm | 70mm | 38mm | |

| Media | Pressure(Bar) | Consumption Per Section (Double Gob) (Nm3/min) | Consumption Per Section (Triple Gob) (Nm3/min) |

| Low Pressure Operating Air | 2.1 | 1.0 | 1.0 |

| High Pressure Operating Air | 3.1 | 1.0 | 1.0 |

| High Pressure Air (Pilot Air of EPVB) | 4.0 | 0.003 | 0.003 |

| Forming Air (Blow and Blow) | 3.1 | 2.4 | 2.7 |

| Forming Air (Press and Blow) | 3.1 | 3.2 | 3.8 |

| Vacuum | 150mbar | 0.2 ~ 0.3 | 0.2 ~ 0.3 |

| Stack Cooling only | 1200 mm H2O | 95 | 90 |

| VertiFlow Blowside and Blank Stack | 1200 mm H2O | 75 | 70 |

| Conveyor | 600 mm H2O | 12 | 12 |

| Lubrication Oil | 80 | 1.3 L/day | 1.3 L/day |

| Cooling Water | 2.1 | 15 L/min | 15 L/min |

| Feeder | BLD89 × 2 |

| S | 400.5 |

| IS Machine Section Number / Dimension | 4 | 6 | 8 | 10 |

| mm | mm | mm | mm | |

| A | 2608 | 2608 | 2608 | 2608 |

| B | 3369 | 3369 | 3369 | 3602 |

| C (Delivery Center Distance 89mm) | 3861 | 3861 | 3861 | 4053 |

| D (Recommended) | 5500 | 5500 | 5500 | 5700 |

| E | 1168 | 1168 | 1168 | 1168 |

| F | 587 | 587 | 587 | 587 |

| G | 1730 | 2264 | 2798 | 3332 |

| H | 3660 | 4828 | 5896 | 6964 |

| I | 1716 | 2250 | 2784 | 3318 |

| K | 2306 | 3236 | 4304 | 6010 |

| L | 1402 | 1402 | 1402 | 1402 |

| M | 2292 | 2826 | 3360 | 3430 |

| N | 1521 | 1521 | 1521 | 1311 |

| Machine Weight | 17T | 23T | 29T | 48T |

Related products

Send Message

Most Recent

More

Other Products

Videos