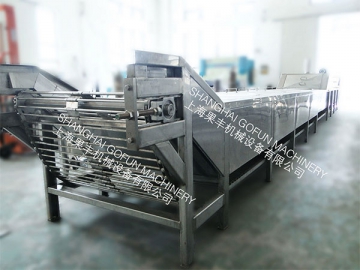

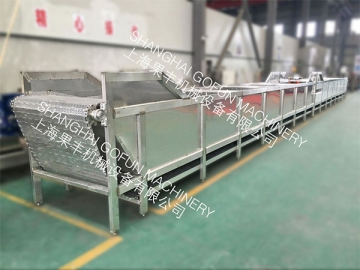

Pasteurization/Cooling Tunnel (Water Immersion Type)

The water immersion type pasteurization and cooling tunnel is specially designed for the pasteurization of dairy products, fruit juices, beverage, and food and medicine after filling or packaging. It prolongs the shelf life by sterilization, heat preservation and cooling. This is an ideal secondary sterilization machine, in particular, for automatic production lines. The process can be designed according to the heating, sterilization, insulation, cooling requirements of different products to meet different storage requirements. The high-precision automatic control system is equipped correspondingly.

The role of vacuum degassing machine is: the removal of liquid air (oxygen), inhibiting the oxidation of products that can cause them to spoil or lose quality.

Features

1. The pasteurization and cooling tunnel can be applied to cans and bottles in various sizes, including round tin cans, glass bottles, and high temperature resistant PET bottles. Diameter: 30-150 mm, height: 50-180 mm.

2. Continuous material feeding and unloading, stepless speed regulation, and adjustable sterilization time and sterilization temperature.

3. Made of food grade 304 stainless steel to reduce pollution and ensure the hygienic quality.

4. Temperature can be set freely and controlled automatically, to maintain a constant temperature.

5. The forced drive shortens the sterilization time, and can make the material temperature uniformity, to ensure sterilization quality.