Coated Aluminum Coil

Coated Aluminum Coil

Materials

This color coatedaluminum coil uses aluminum-manganese-magnesium alloy which is a kind ofaluminum material mixed with manganese and magnesium. The alloy material provides higher tensilestrength and stretching strength and better oxidation and corrosion resistingproperties than common aluminum.

Technical Specifications

Aluminum coil width: 200mm-1,590mm

Aluminummaterial thickness: 0.08mm -1.2mm (±0.02mm)

Outerdiameter of aluminum coil: ≤1,200mm

Aluminum coilweight: ≤3,000kg /coil

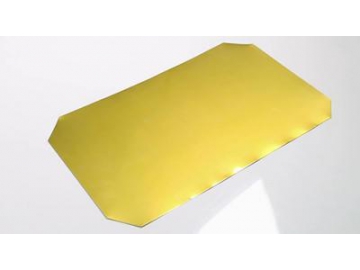

The colorcoated aluminum coil can be cut into sheets in any size.

Features

The color coated aluminumcoil uses 3004 Al-Mn-Mgalloy as the substrate, which undergoes desertification, cleaning and passivation before being paintedwith the most advanced KANAR500 and HYLAR5000 fluorocarbon (PVDF) resincoating. The color coated aluminum coil, made using famous branded paints whichare guaranteed to be weather resistant for over two decades, has the advantagesof high strength, corrosion resistance and high weather ability. It can becustomized in terms of color.

Application

The color coated aluminum coil is used for large steel structure factorybuildings, exhibition halls, stadiums, airports, railway stations, ceilings,and more.

The color coated aluminum sheet in different thickness can be cut, pressed,punched and folded to suit use in large, long span roofing and siding systems.

It can be cut into small pieces and processed to accommodate application needsin indoor decoration.

image005.png

Coil Coating Process

(1) Cleaning and pretreatment

(2) Primer coating

(3) Top coating

(4) Laminating or embossing

A.Bare metal is uncoiled

B. Coil splicing

C. Accumulator stack(entry)

D. Metal degreasing, cleaning,rinsing & chemical pretreatment

E. Drying oven

F.Primer unit – one or both sides

G. Curing oven

H.Coating unit-top coat applied one or both sides

I. Curing oven

J.Laminating – one or both sides , or embossing

K.Accumulator stack (exit)

L.Recoiling finished metal

Testing

The company has its own testinglaboratory equipped with all necessary testing instruments. The laboratoryconducts testing on the entire production for export as well as for domesticmarket.