Circular Vibrating Screen, YAK/YAKR

Product Brief Introduction

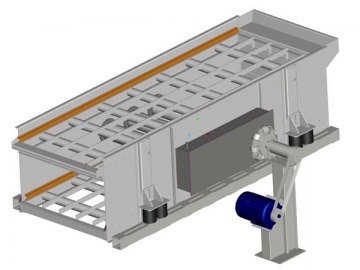

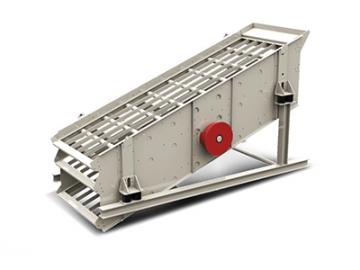

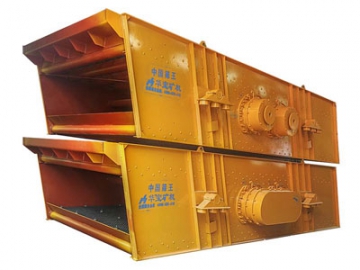

The circular vibrating screen uses an eccentric circle drive to achieve a powerful vibration effect. The vibratory screen helps sift materials for industries such as coal mining, building material production, chemical, power generation and mineral processing.

Designed with varied screen plate quantity and screen mesh size, the circular vibrating screen supports maximum feeding size of 200mm and offers maximum feeding capacity of 800t/h. On the basis advanced American technologies, the screening equipment adopts a ring-grooved cold riveting connection frame structure, which helps reduce noise and facilitate convenient maintenance.

Detailed Features of the Circular Vibrating Screen

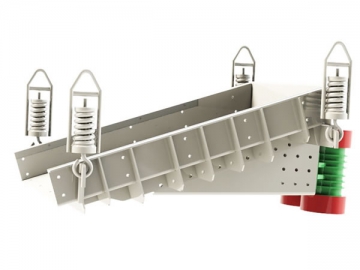

- Vibration screen

- Damping spring for the vibrating screen

- Gear case

1. The screening machine features a lubrication system that uses grease and diluted oil lubrication for different parts.

2. The screen surface of the circular vibrating screen has a mesh grid, perforated screen plate, and a polyurethane sieve plate.

3. The electric motor can be installed on the left or right side. The rated voltage of the vibrating equipment's electric motor is 380V. If you need a different rated voltage anti-explosive motor, you should make a note when you order the product.

Basic Parameters of the Circular Vibrating Screen

| Model | Screening layer | Screening area (m2) | Mesh hole size (mm) | Max. feeding size (mm) | Process capacity (t/h) | Vibration frequency (R/min) | Double amplitude (mm) | Motor power (kw) | weight (kg) |

| 2 | 7.2 | 5-50 | 200 | 50-150 | 820 | 5-10 | 7.5 | 5500 | |

| 3 | 5-50 | 200 | 50-200 | 820 | 5-11 | 11 | 6076 | ||

| 2 | 8.64 | 200 | 50-180 | 820 | 5-10 | 11 | 6500 | ||

| 3 | 5-80 | 200 | 50-230 | 820 | 5-11 | 15 | 6930 | ||

| 2 | 10.8 | 200 | 50-260 | 820 | 5-10 | 15 | 7200 | ||

| 3 | 200 | 50-220 | 820 | 5-11 | 18.5 | 7700 | |||

| 1 | 12.6 | 6-50 | 200 | 100-300 | 748 | 5-10 | 15 | 5893 | |

| 2 | 200 | 100-260 | 5-10 | 18.5 | 8560 | ||||

| 3 | 200 | 100-220 | 5-12 | 22 | 9950 | ||||

| 2 | 14.4 | 200 | 150-400 | 5-11 | 22 | 9150 | |||

| 3 | 200 | 150-450 | 6-14 | 22 | 10634 | ||||

| 2 | 18 | 200 | 250-800 | 6-14 | 30 | 12116 |

| Overall Material | Screen Mesh Material | Layer | Motor Brand | Lubrication System | Flowchart & Layout Design | Sample Supply |

| Polyurethane, wire or customized | 1,2,3 or customized | ABB, OLI-WOLONG or as per your request | Grease | Available | Available |