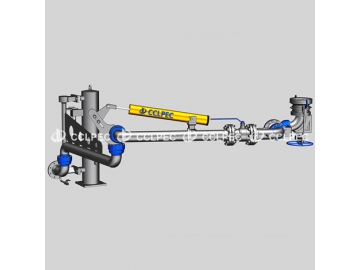

Column Type Gangway

Gangways are essential equipment for crew and operators to safely embark and disembark of oil tankers. CCLPEC CL3 column type gangway is mainly composed of bulwark ladder, slewing platform and column. The front ladder is able to perform horizontal motion, luffing motion and telescopic motion around the column. The CL-3 column gangway is applicable to ships with loading capacity of below 50,000 DWT.

Available Configurations

Gangway main body, wireless remote control, ground operation control, electrical control system, hydraulic system, lighting system, piping and wiring, embedded parts of foundation, supporting tools and spare parts, and optional jib crane;

Features

- The design of the gangway is carried out on the basis of comprehensive consideration of ship type, jetty structure, meteorological and hydrological conditions, earthquake level and all stresses on jetties.

- The bulwark ladder can slew horizontally and luff up and down, so as to allow that the triangle ladder landing smoothly on the deck. It is ergonomically designed to provide crew and operators with comfortable embarking experience.

- Jib crane is configurable to be located at the top of the column gangway, capable of implementing hose lifting operation and ship embarkation while saving area.

- The gangway is usually used with the consideration of operating envelope of loading arm and the explosion protection requirements of jetty. All the electrical equipment are compliant with the requirements of ATEX and IEC explosion proof certifications.

- The structure of the bulwark ladder is available in folding type and telescopic type, which is selectable according to the applications of the gangway.

- The welding process is accomplished by qualified welding personnel, and it can be submitted to the client for approval.

- The surface treatment and corrosion resistance treatment can also be verified by client, aiming at adapting to the application conditions of the marine environment.

Highlights

- Through the rotating ladder installed on the column or maintenance ladder located next to the main structure, operators or maintenance personnel can easily access to the slewing platform of the column gangway.

- Welding process and surface treatment process can be submitted to the client for approval.

- The bulwark ladder can be manually retracted to the storage position during a power failure.

Specifications

| Material of bulwark ladder | LF5 aluminum alloy / Q345B steel |

| Width of bulwark ladder | 700mm |

| Motions of bulwark ladder | Telescopic/folding |

| Luffing mechanism | Working class: M4 |

| Luffing speed: 36-72 degree/min | |

| Slewing mechanism | Working class: M4 |

| Slewing speed: 0.17 r / min | |

| Slewing angle: ±90 | |

| Hydraulic system | Working height: M4 |

| Working pressure: 16MPa | |

| Electrical system | Motor protection: IP55 |

| Equipment protection: IP65 | |

| Explosion proof: ExdIICT4 |

Related products

Send Message

Most Recent

More

Other Products

Videos