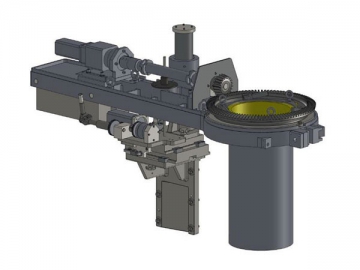

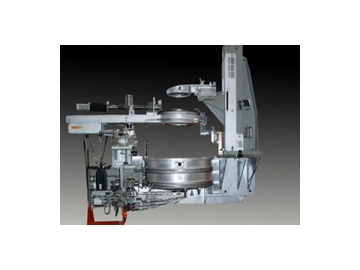

Gob Feeder, GS Series

The GS series gob feeder uses precision servo systems. It includes the dual motor shears, tube height and rotation mechanism, and the servo plunger mechanisms for gob forming. It is used to produce high quality gobs over a very wide production range.

The servo feeder is designed to serve as a substitute of conventional electronic cam-driven system. Due to an intelligent control system, the gob feeder system features concerted action among the feeder plunger, revolving tube and the shear mechanism. High precision plunger and shear motions ensure improved gob weight control and production speed.

Technical Specifications| Type | Spout Dimensions (mm) | |||||||||||

| Width | 410 | 460 | 560 | |||||||||

| Depth | 190-230 | 210-254 | 210-278 | |||||||||

| Bore Size | 127 | 152 | 178 | 178 | 203 | 230 | 254 | 178 | 203 | 230 | 254 | |

| 910 | Single Gob | l | l | l | l | l | l | l | l | |||

| Double Gob | l | l | l | l | l | l | l | l | ||||

| Triple Gob | l | l | l | l | l | l | l | l | ||||

| 660 | Single Gob | l | l | l | l | |||||||

| Triple Gob | l | l | l | l | ||||||||

| Minimum Class Flow t/d | 10 | 10 | 10 | 25 | ||||||||

| Maximum Class Flow t/d | 30 | 40 | 50 | 120 | ||||||||

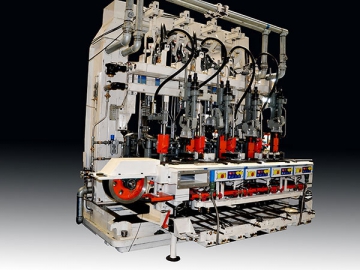

1. Dual Motor Shears

The shear mechanism serves to cut glass portions from the gob feeders and is controlled by a computer. The shearing angle varies with the position of individual section machines, ranging from 90 degree left angle to 30 degree right angle.

Advantages

Blade motion rectangular to the center line (at the time of cut)

Dwell time of the shears in the opened position, which ensures improved cooling conditions for the shear blades

Preselectable motion profiles

Has max. production speed up to 250 cuts per minute

Almost maintenance-free operation

2. Servo Plunger

The single drive feeder plunger is a servo mechanism based on the FlexIS control technology, which uses electronic cam. Individual plungers are driven up and down by the servo motor. There is no operating air to assist the plunger motion. Only cooling air is used for the servo motor.

3. Servo Tube Mechanisms

The tube height and tube rotation mechanisms employ servo motors to control the elevation of the refractory tube above its sealing surface on the refractory spout, as well as the rotation speed and direction of the tube. The tube elevation controls the amount of glass located above the orifice ring. This is a major factor in controlling gob weight.