IC Anaerobic Reactor (Internal Circulation Reactor)

Application

Internal circulation reactors are used in the treatment of highly concentrated organic wastewater, such as wastewater from potato processing, endive processing, beer production, citric acid and paper production, starch wastewater, ethyl alcohol sewage and other light industrial food.

Design principle

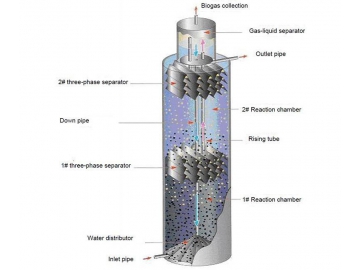

The internal circulation reactor is made using a two layer UASB reactor that connects in a series. This reactor is divided into 5 zones: mixed zone, first anaerobic zone, second anaerobic zone, sedimentation zone and gas/liquid separation zone.

Mixed zone: The water enters the bottom of the reactor, where the sludge particles and the water/sludge mixture will mix in the mixing zone.

The first anaerobic zone: The sludge -water mixture of the mixed zone enters into the first anaerobic zone, where the primary parts of the organic matter transform into methane using a highly concentrated sludge. The mixture rising and violent disturbing of the methane will make the sludge inflate, maintain fluidization, and increase the sludge/water contact, thus ensuring the sludge retains a high level of activity.

Gas-liquid separation zone: The methane found in the risen mixture is separated from the sludge water and expelled out of the treatment system. The sludge water mixture then flows along the return pipe into the mixed zone at the bottom, and thus, completes the recycling of the mixture.

The second anaerobic zone: The second anaerobic zone has a low sludge concentration, thus there will not be a large methane output.

Sedimentation zone: The sludge-water mixture of the second anaerobic zone is solid-liquid separated in the sedimentation, then the supernate is expelled through the outlet pipe, with the subsided sludge particle returning to the sludge bed of the anaerobic zone.

Looking at the working principle of the internal circulation reactor, the device achieves an SRT>HRT and obtains a high concentration of methane through the 2 layers of the 3 phase separator. Through the violent disturbance of mass methane and internal recycling, the sludge and water will come into significant contact, thus facilitation an excellent mass transfer effect.

Features

(1) High sludge concentration: The organic loading is over 3 times that of the common anaerobic reactor.

(2) Small volume: Large height-diameter ratio ( 4~8 generally); Small occupied space

(3) Strong shock resistance, Strong loading ability

(4) Self automatic recycling; Dose not need the extra power.

(5) Good water output stability.

(6) Short starting period: High activity of the sludge; The starting period is 1~2 months generally.

(7) High use value of the methane.

Customization

Please provide the treatment volume, water quality and material requirements.

Huaneng Jinhao manufactures water treatment equipment and domestic sewage treatment plant to global markets, with decades of experience, we can fabricate any water treatment equipment and machinery like industrial water decanter, water filtration equipment, sludge separation equipment, and the auxiliaries of water treatment equipment.

Index

anaerobic digestion, wastewater treatment, sewage treatment