Corrugated Sheet Roll Forming Machine

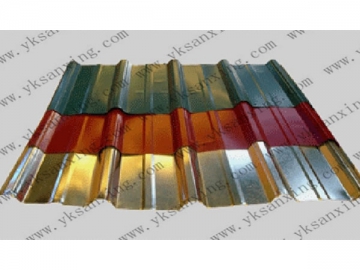

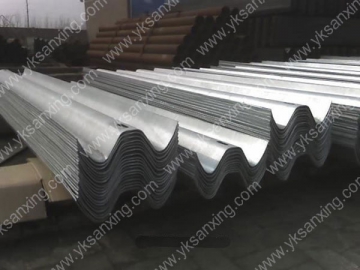

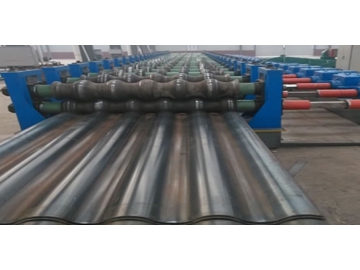

The flat steel corrugated roll forming machine is used to press 0.3-1mm thick colored steel sheets through a rolling and cold bending process to form wave pattern sheets. These colored wave pattern sheets will then be used in the construction industry for roofs, interior walls, and external wall boards for storehouses, residential homes, or industrial places and worksites.

The wave sheets resulting from the use of the flat steel corrugated roll forming machine are light weight, strong, and come in multiple colors. They are earthquake proof and fireproof, as well as featuring other useful characteristics for construction projects. In order to meet all requirements for high and low strength sheets, Sanxing has improved the design of the forming press. A herringbone roller was added between the wave crests of the frames to give the pressed sheet its flat and beautiful appearance, as well as its strength.

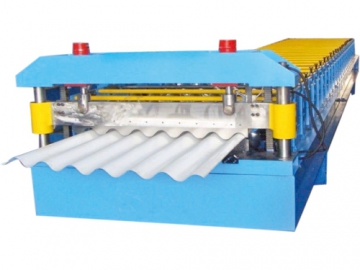

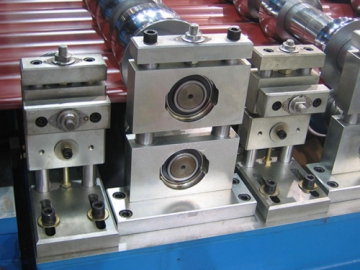

Each roller on the flat steel corrugated roll forming machine are forged through intense processes using high quality steel. Processes include high frequency hardening, quenching and hardening, and their surfaces are then plated with hard chromium to make them smooth and wear resistant. The flat steel corrugated roll forming machine has a computer to control the length and other measurements.

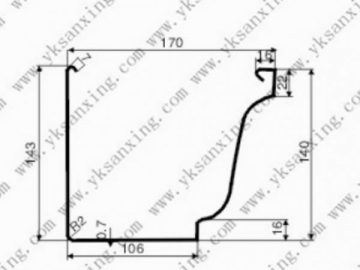

Main Types of the Flat Steel Corrugated Roll Forming Machine| Types | Width of the coil | Width of the formed sheet | The depth of the groove | Thickness of the coil | Usage |

| 1000 mm | 840 mm | 25 mm | 0.3-0.6 mm | Roof | |

| 1000 mm | 900 mm | 15mm | 0.3-0.6mm | Wall | |

| 1000 mm | 930 mm | 14mm | 0.3-0.6mm | Wall | |

| 1250 mm | 1000 mm | 35mm | 0.5-0.8mm | Roof |

Note: Sanxing offers more than one hundred different profiles. Other dimensions and types are also available upon request. If a company has a special design request, we manufacture the client's flat steel corrugated roll forming machine within a month.