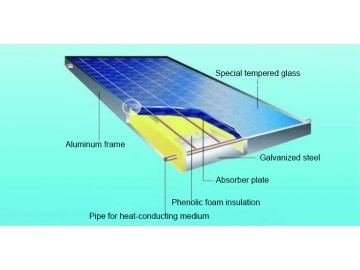

Flat Plate Solar Collector

Working Principle

Sunlight passes through the glazing and strikes the absorber plate which then heats up, changing solar energy into heat energy. The heat is then transferred to the fluid or gas passing through attached pipes through a convective heat transfer process. The absorber plate’s glass cover is often painted with a ‘selective coating”, allowing light to pass through while still blocking infrared light, allowing the absorber plates to better absorb and retain heat.

Absorber plate:

Absorber plates are commonly painted with an absorbent coating, allowing them to absorb and retain heat.

Phenolic foam insulation:

It is designed for preventing heat collector heat loss. The phenolic foam insulation is made of nonabsorbent materials with a small thermal coefficient to ensure the excellent thermal insulation effect.

Glass covers:

These covers allow light to pass through while blocking infrared light, thus effectively reducing energy loss.

Shell (frame, baseplate):

It is used to integrate different components, including the absorber plate, glass covers, insulation materials, and more. It is manufactured using steel, color steel plates, aluminum plates, embossed aluminum plates, and stainless-steel plates. The shell features an excellent rigidity and strength, as well as an easy installation.

HSJ115

| Model | HSJ115 | |

| Absorber | Coating | Blue titanium |

| Structure Type | tube sheet | |

| Solar Absorption | ≥95%(@AM1.5) | |

| Thermal Emittance | ≤5%(@80℃) | |

| Coating Material | Aluminum | |

| Header Pipe | Copper φ42×1.5mm | |

| Riser Pipe | Copper φ8×0.45 mm | |

| Frame | Overall Dimensions | 5030×2270×140 mm |

| Material | High- grade aluminum 6063-T5 | |

| Surface Treatment | Frosted with white color | |

| Sealing | High weatherproof silicone sealant | |

| Cover plate | Material | Super white low iron tempered glass |

| Thickness | 3.2mm | |

| Solar Transmittance | ≥91.5 % | |

| Bottom | Material | Color-coated sheet |

| Thickness | 0.4mm | |

| Insulation | Material | Bottom: PU Glass wool |

| Side: PU | ||

| Thickness | Bottom: 30mm | |

| Side: 40mm | ||

| Connector | Size | DN40 |

| Qty. | 2 pcs | |

| Performance | Rated Working Pressure | 1.0MPa |

| Instantaneous Efficiency | 0.81 | |

| Heat Loss Coefficient | 3.8W/m·K | |

| Total Area or Collector Area | Total area: 11.5㎡ | |

| Aperture Area | 10.5㎡ | |

| Thermal Performance | 1. When the environmental temperature is 5℃, the amount of solar irradiation is 20MJ/㎡, it means the energy output of each solar collector is more than 120MJ every day. | |

| 2. All performance meets GB/T6424-2007 criterion. | ||

| Raining Test | No leakage | |

HSTC500

| Model | HSTC500 | |

| Absorber | Coating | Blue film Coating |

| Structure Type | Pipe-plate | |

| Solar Absorption | ≥95%(@AM1.5) | |

| Thermal Emittance | ≤5%(@80℃) | |

| Absorber Material | Aluminium sheet | |

| Header Pipe | Copperφ22×0.6mm | |

| Grid Pipe | Copper 12-φ10×0.5 mm | |

| Frame | Overall Dimensions | 2050x1050x100 mm |

| Material | Super grade aluminum 6063-T5 | |

| Surface Treatment | Painting black | |

| Sealing | High resistant silicone | |

| Cover plate | Material | 1. Hollow tempered glass(laying AR subtracting film) 2. Double glazed |

| Thickness | 3.2-6-3.2mm | |

| Solar Transmittance | ≥85 % | |

| Bottom | Material | Polyurethane Aerogel |

| Insulation | Material | 35K glass wool |

| Thickness | 30mm | |

| Connector | Size | G3/4 |

| Qty. | 4 pcs | |

| Performance | Rated Working Pressure | 1.0MPa |

| Instantaneous Efficiency | 0.72 | |

| Heat Loss Coefficient | 2.79W/m·K | |

| Total Area or Collector Area | Collector area: 2.15 ㎡ | |

| Aperture Area | 1.87㎡ | |

| Thermal Performance | It can output 518W/㎡power under conditions of solar irradiance of 1000W/㎡with 80℃ temperature difference. | |