Plasma Cutter

With our plasma cutter, the cutting process involves utilizing extremely sharp and high-temperature plasma arc to quickly pierce through the workpiece and then blow away the molten material.

In general, the uncompressed gas (at atmospheric pressure) in an electric arc is partially ionized. The temperature of such so-called free-burning electric arc is ranging from 6,000℃ to 8,000℃.

When imposed to high pressure, the free-burning electric arc will ionize almost all the gas within it, thereby creating a plasma jet with high velocity, high current density and small conductive cross-sectional area. The plasma jet will immediately reach temperature ranging from 15,000℃ to 30,000℃, quickly melting down the metal processed.

-

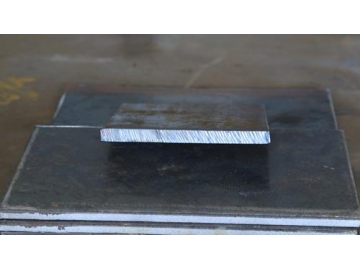

Plate material: 8mm carbon steel

cutting current: 40A

cutting pressure: 0.4Mpa

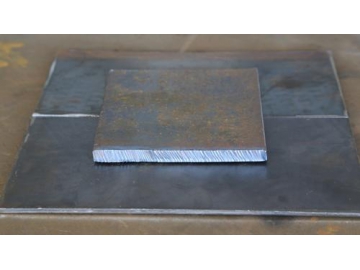

Plate material: 8mm carbon steel

cutting current: 40A

cutting pressure: 0.4Mpa

Working Principle

- Electrode

- Nozzle

- Shielding cover

- Plasma arc

- Weld bead

- Workpiece

Features of Plasma Cutter

- Our plasma cutter features low cost, great cutting capacity and superior cutting quality.

- It can be applied for cutting varieties of electrically conductive materials, such as carbon steel, stainless steel, aluminum, oxidized or rusty metals.

- The plasma cutting machine is able to ensure smooth cut. In addition, it can also be used for cutting sheet metal in curved or angled shape.

- The plasma cutting equipment also features easy operation. Automatic cutting can be achieved when integrating the cutter with matched CNC.