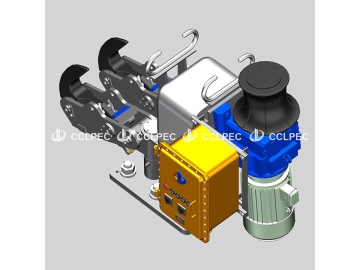

Hydraulic Release Quick Release Mooring Hook

CCLPEC provides customized quick release mooring hooks. This hydraulically operated quick release mooring hook is configured with mooring capstan mechanism, locking mechanism, hydraulic release mechanism, steel hooks, steel support structure, control panel, foot switch and base plate. Coupled with hydraulic control system, the automation of mooring hook can be significantly improved. Mooring rope will be easily released by simply pressing the button or pushing the release lever. Mooring rope will not be released from quick release hook until the locking mechanism is opened, which prevents the undesired opening of the hook. Laser berthing aid system and mooring tension monitoring system are available upon request.

Features

- The quick release mooring hook is made of alloy steel castings. The hook release mechanism installed within the structure to prevent the mooring rope from slipping.

- All hooks are tested at a load which equals to 125% safe working load (SWL), enabling the hook to be released under the full safe working load.

- Anchor bolts, nuts and washers are standard galvanized metal fasteners, which will be delivered to customers in advance, allowing customer to pre-embed the anchor bolts before any hooks are delivered to the installation location.

- The load on mooring ropes is finally transferred to the concrete foundation through hook support structure and base plate bolts.

Specifications

| Hook quantity | 1, 2, 3, 4 |

| Release load per hook | 250〜2500kN |

| Test load per hook | 1.25 * SWL |

| Handle operation force | < 170N |

| Rotation angle of hook | Horizontal: -90°~ 45° -45°~ 45° (central hook) -45°~ 90° Vertical: -5°〜45° |

| Electric capstan traction force | 10 ~ 50 KN |

| Electric capstan traction speed | 10 ~ 30 M/min |

| Motor | Explosion-proof level: ExdIIBT4 Protection rate: IP65 |

| Foot switch | Explosion-proof level: ExdIIBT4 Protection rate: IP66 |

| Explosion-proof control panel | Explosion-proof level: ExdIIBT4 Protection rate: IP66 |

| Surface treatment | Metal structural parts are sandblasted for rust removal, and coated with anticorrosion coatings. |

| Releasing method | Hydraulic release |

| Embedded parts | Low carbon alloy steel |

| Fasteners | Low carbon alloy steel and stainless steel |

| Towing capacity per hook (ton) | 35, 45, 60, 75, 100, 125, 150 |

| Manual operation force for hook reset | ≤200 N |

Related products

Send Message

Most Recent

More

Other Products

Videos