Soldering Iron

Request a Quote

- High cost performance: simple and exquisite, the professional design of the soldering iron is conducive to the outstanding performance.

- Safe engineering: the power line made of pure copper wire in big diameter can provide sufficient power, and has outstanding bending endurance.

- Optimal heating element: the heating element for the soldering tool is made of high-quality thermal fuse. The double wire wrapping effectively prevents the soldering iron from short circuit. Therefore, the service life is prolonged, accordingly.

- Comfortable grip: conforming to human engineering, the heat-resisting resin molding fits closely with hand geometry.

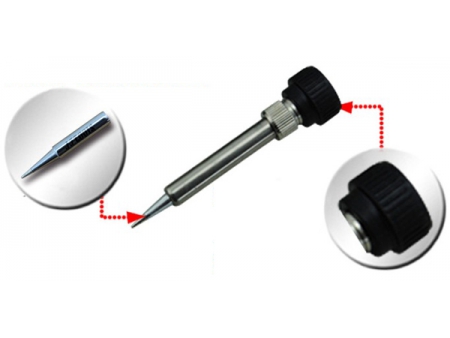

- The original soldering iron is made of pure oxygen-free copper, plated with pure iron or tin. The rapid heat conduction makes for efficient lead-free operation.

- Using imported high temperature plastic injection moulding, the product can withstand high temperature, and will not get deformed easily.

The original heating element, which is characterized by long service life, accurate control and minimal drain voltage, is applicable for precise welding.

Soldering Station Selection Method- 20W and 40W---applicable for welding small element on PCB

- 40W and 60W---specially offered for low voltage switch and transformer

- 60W and 80W---available for soldering wire rod, element with radiator, as well as the solder joint requiring big heat consumption.

- For first time use, there is small amount of smoke produced. Please feel at ease with it.

- The welding tool shall be positioned at the high-quality iron stand to avoid scalding and fire disaster caused by high temperature.

- Do not solder component with iron core pulled out. Otherwise, the service life of the iron core will be shortened.

- Natural cooling is highly recommended. Quick cooling with water will result in short service life of the soldering iron.

- In case there is integrated circuit or COMS element, soldering station with 3-core power line shall be selected to avoid damage to the device caused by induced voltage or drain voltage.

- Utilization of special long-life solder tip is not suggested.

- Carefully examine whether the tin at the top of the solder tip is penetrated or seriously oxidized. The solder tip shall be immediately replaced in case penetration is found. For oxidation, brush and sand paper with over 800# grit shall be used for grinding. It is prohibited to conduct grinding with the sand paper or grinding wheel with the grit no more than 800; otherwise, the service life of the solder tip will be seriously affected.

- Stain on the PCB rework equipment is generally caused by the splatter of the scaling powder. Ethyl alcohol shall be employed for cleaning.

- Before using, preheat the soldering iron until the temperature for welding is obtained. Afterwards, slightly wipe the solder tip with watersoaked sponge to remove the oxide layer.

- Immediately, cover the solder tip with newly melted solder tin.

- Preheating shall be conducted on the soldering part with the solder tip.

- After short time preheating, insert the solder tin into the solder tip to have it melted until it flows to the welding position naturally.

- Remove the soldering iron immediately when the solder tin is well integrated with the welded device to avoid excessive welding. Additionally, premature removal of the solder tip will lead to cold welding.

- Under the circumstance welding is completed, clean and cover the solder tip with tin before poweroff.

- Before replacing iron core, check if there is solder tip on the core. The old solder tip shall be removed before the replacement of the iron core.

- The acidized substance inside stainless steel tube shall be eliminated first before replacing the iron core.

- To avoid solder tip oxidation and insulativity reduction of the iron core, the soldering iron shall be kept in the circumstance free from high temperature and humidity.