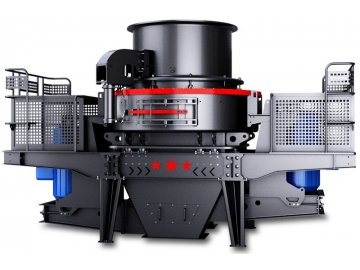

New Model VSI Sand Making Machine

Unique rock on rock crushing method is adoptedin new model VSI sand making machine and this product is appropriate formaterials with high abrasive property and silica content. And high speed rotorwith crushing chamber is also used. Velocity, rather than surface force, isused as the resulting force to break stone particles. As a result, force can beevenly applied on the surface of the rock. In this machine, materials to becrushed hit other similar covering materials at very high velocity. Atthe same time, same crushed particles come in and collide with other particlesfrequently. Through high impact of the kinetic energy of each other, feedparticles acquire velocity again. Finally, particles crack and crush under theirmutual hit and force. New model VSI sand making machine can give cubic shape offinal product. At the same time, output size of product in fine or coarseaggregates can be controlled by adjusting velocity of input materials and thedistance between the end of the rotor and the impact point.

Detailed Specifications

| Model | VSI5818 | VSI8520 | VSI9528 | VSI1240 | |

| Capacity(t/h) | Center and ring feeding | 120-180 | 200-260 | 300-380 | 450-520 |

| Center feeding | 60-90 | 100-130 | 150-190 | 225-260 | |

| Max. feeding dimension | Soft material | <35 | <40 | <45 | <50 |

| Hard | <30 | <35 | <40 | <45 | |

| Rotation speed(r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Overall dimension (LxWxH) (mm) | 3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5000×2700×3300 | |

| Weight(t) | 7.8 | 10.3 | 16 | 22 | |

| Power | 380V;50Hz | ||||

| Inspection scope of vibrating sensor | 0.1-20mm/s, continuously adjusted | ||||

| Lubrication System | Double oil pump motor power | 2×0.31 | |||

| Safety | Double oil pump, stopping working without oil or hydraulic pressure; temperature falling when water cools; starting the motor by heating in winter. | ||||

| Overall dimension (LxWxH) | 820×520×1270 | ||||

| Gasoline tank heating power (kw) | 2 | ||||

Working Principle

The first type is center feeding. To be more specific, raw materials fall downinto feed hopper first and then enter impellor through central entrance hole.Materials are accelerated in high-speed impellor and thrown out at speed of60-75m/s. When hitting impact plate, they are crushed. Finally, final productsare discharged downwards through outlet.

The second type is ring feeding. Precisely, raw materials fall down into feedhopper through ring. Then they are divided into two parts by material-dividingplate. One part enters impellor through the center of material-dividing plate.To the contrary, the other part falls down from outside of material-dividingplate. Materials are thrown out by impellor at the speed of 60-75m/s. Then theycollide with materials coming down from outside of material-dividing plate. Inthis way, materials are crushed.

There are many features of new model VSI sand making machine.

1. Advanced double-pump oil lubrication system is adopted in this product toguarantee lower temperature, longer service life and reliable operation.

2. Main shaft of new model VSI sand making machine is equipped with importedprecision rolling bearing. As a result, maintenance cycle is lengthened andproductivity is increased.

3. It is very easy to remove hydraulic lifting mechanism of upper cover fromcover so power during maintenance can be reduced.

4. Over-vibration device is equipped as well. This device can alarm whenvibration surpasses a stipulated figure stop the machine to protect it.

5. To make sure new model VSI sand making machine works normally, specialdust-proof design is adopted in main shaft bearing to fully prevent dust fromentering bearing lubrication part.

6. To meet different requirement, center feeding and ring feeding can cometogether due to special feed opening structure. In addition to that, new modelVSI sand making machine can not only crush stone, but also iron.

7. Shape of material-through device is better designed, thus utilization ratiois improved.