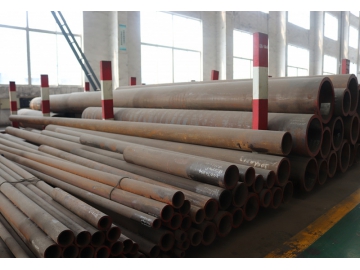

Nickel Titanium Alloy Pipe

Applications

Nickel titanium alloy pipe is mainly used in fields that ordinary pipes cannot accommodate, such as chemical, petroleum, metallurgy, light industrial machinery, instrument, power generation, sea water desalination, medical device, salt manufacturing, electroplating, environment protection, and copper industries.

Advantages

1. Our nickel titanium alloy pipe performs well in high temperature environments. It can work normally for a long periods of time in temperatures up to 450~500℃ and retain its original strength.

2. With a layer of even and dense oxide film on the surface, this premium alloy tube is able to resist corrosion caused by different mediums.

3. The nickel titanium alloy pipe is characterized by its smooth surface, small density, high strength, and light weight.

As a professional pipe production enterprise, we provide a variety of temperature resistant nickel titanium alloy pipes including U-shape pipe, square pipe, rectangular pipe, oval pipe and irregular pipes. The alloy tubing can be processed by cold drawing, hot extrusion, piercing, welding, straightening, hot bending, annealing, quenching, pickling, etc.

Technical Parameters of Nickel Titanium Alloy Pipe| Design and Manufacture Standard | ASTM/ASME, DIN, EN, JIS, GOST |

| Type/Shape | Straight, U-shape, square, rectangular, oval, irregular |

| Raw Material | UNS N08800, UNS N08825, UNS N06625, UNS N08926, Gr.1, Gr.2, Gr.3 |

| Manufacture Process | Cold drawing, hot extrusion, piercing, welding, straightening, hot bending, annealing, quenching, pickling, etc. |

| Test and Inspection | NDT, chemical analysis, hydrostatic test, mechanical property test, appearance and dimension inspection |

| Size NB/SCH Metric | Hot extrusion pipe, cold drawn pipe, welded pipe |

| 1/8”~26” * Sch5S-XXS/ Hot Extrusion Pipe | OD: 51~219mm; WT: 6~32mm Cold Drawn pipe: OD: 6~630mm; WT: 0.5~35mm Welded pipe: OD:6~3000mm; WT: 0.5~65mm |