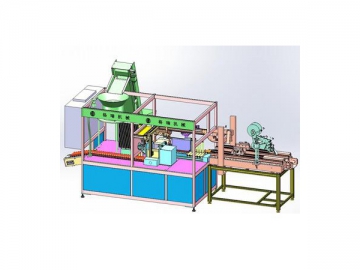

Automatic Case Erector and Sealer

The automatic case erector and sealer is mainly used for matching automatic piston fillers, and it integrates sealant nozzle sorting, sealant nozzle adding, automatic case opening, automatic packaging following packing specification, product qualification placing, upper and lower sealing of case and security-label labeling.

| Packing specification | 5×5 25 cartridges/case 4×6 24cartridges/case |

| Packing speed | 2-3 boxes/min. |

| Overall power | 5KW |

| Air pressure | 0.7MPa |

| Air consumption | 250L/min. |

| Machine size (L x W x H) | 5200x2400x2800mm |

| Net weight | 1.8T |

Note: Great can match the voltage and frequency of the equipment based on customers in different regions.

- Sealant nozzle installing 01: Sealant nozzle storage hopper

02: Sealant nozzle sorting device

03: sealant nozzle installing device - Conveying mechanism 01: Product without sealant nozzle

02: Product with sealant nozzle

03: Product conveying mechanism - product stacking 01: Case erector

02: Product stacking mechanismeProducts are stacked following specifications of 5×5 25 cartridges/case or 4×6 24cartridges/case. Driven by servo motor module, it is quick and stable without omit, having 100% qualification rate.

- Automatic case erecting 01: Case erector

02: Product stacking station - Pacing label and qualification 01: Label feeder

02: Label applicator - Up and bottom sealing of the case 01: Case sealer

02: Auxiliary clip for case sealingThe sealing has adjusting device to ensure a good sealing effect, aligning seals with uniform sealing clearance less than 1.5mm.

- Security label labeling 01: Height adjusting hand wheel

02: Labeling disk

03: Labeling position

04: Label tractor - Fault alarming and displacing