CCGA (Ceramic Column Grid Array) Solder Column

CCGA (Ceramic Column Grid Array) solder columns, as a type of novel solder material, are developed for microelectronic with higher demand in reliability, suitable for military industry, aerospace industry, etc. With CCGA packaging technics, electronic components feature better reliability than their BGA-packaged counterparts, for they are ensured excellent anti-vibration, anti-thermal-fatigue and anti-moisture performance. Worth noticing that, CCGA packaging is a good solution for overcoming CTE mismatch between chip and PCB.

JUFENG offers CCGA solder columns of diameters from 0.2mm to 0.9mm, lengths are customizable ranging from 1mm to 4mm. Our advanced process ensures the columns very low voidage, thus very good reliability.

Features- By our special manufacturing process, micro-coil springs feature fine precision and end surface flatness, thus ensuring package assembly precision and decreasing noncoplanar error.

- Special anti-oxidation process is applied for our micro-coil springs, which ensures low oxidation in end surface, thus guarantees good wetting performance in soldering.

- Special molding process is applied for our micro-coil springs, which ensures extremely low voidage, thus guarantees the IC good on-duty reliability.

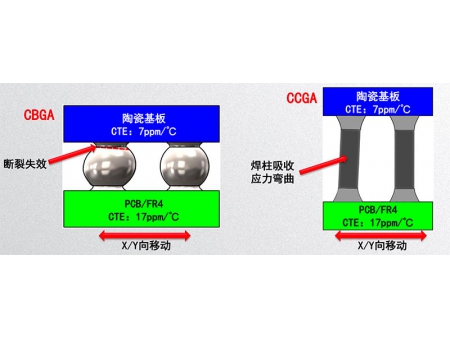

- CBGA (Ceramic Ball Grid Array) packages feature relatively poor reliability due to solder balls’ disability in well-absorbing strain caused by CTE mismatch between ceramic substrate and PCB. While CCGA packages reveal much better reliability with the same load, since solder columns are able for well-absorbing the CTE mismatch induced strain, therefore resisting more shocks and deformations. As a result, CCGA packages are suitable for chips in larger sizes.

| Tin columns | Material | Size (mm) diameter*length | Note |

| Pb90Sn10 | 0.5*2.2 | Material and size are customizable | |

| 0.5*2.5 | |||

| 0.5*1.5 | |||

| 0.4*2.2 | |||

| 0.4*1.5 | |||

| 0.3*1.27 |

| Copper columns | Material | Size (mm) diameter*length | Plating | Note |

| TU2 | 0.5*2.2 | Sn/Ni/Au, etc. | Material and size are customizable | |

| 0.5*2.5 | ||||

| 0.5*1.5 | ||||

| 0.4*2.2 | ||||

| 0.4*1.5 | ||||

| 0.3*1.27 |

| Copper wrapped columns | Material | Size (mm) diameter*length | Note |

| Core: Sn20Pb80 Ribbon: Cu Plating: Sn63Pb37 | 0.51*2.21 | Material and size are customizable | |

| 0.51*2.31 | |||

| 0.51*2.54 | |||

| 0.51*3.81 |

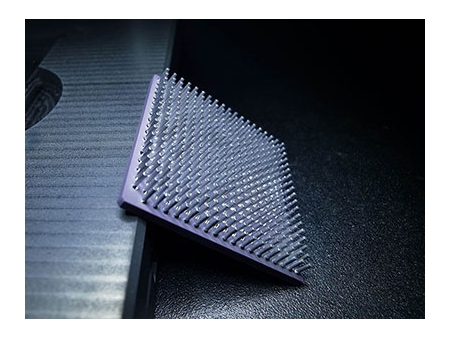

As a novel type of solder columns, micro-coil springs are suitable for interconnect for CCGA IC packages in harsh environments. Micro-coil springs exhibits mechanical performance, in tests using daisy chain test vehicles, the springs absorbed extreme shock of up to 50,000g before failing. Micro-coil springs are applied commercially in aerospace, avionics, military, down-hole oilfield drilling and automotive electronics.

| Micro-coil spring | Material | Size (mm) diameter*length | Plating | Note |

| BeCu | 0.51*1.27 | Sn60Pb40(2.5μm) | Material and size are customizable | |

| 0.51*1.27 | Ni/Cu Au:0.25μm Ni:0.76-1.5μm | |||

| 0.4*1.0 | Sn60Pb40(2.5μm) |