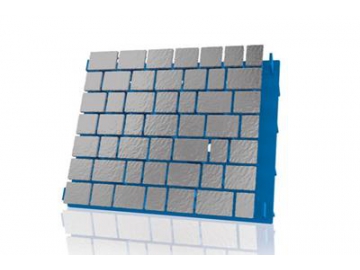

Block and Brick Surface Design

Free surface and system based design is the most advanced design process in the concrete industry in order to achieve a natural stone appearance. Based on the feedback from customers and good market reputation, we are proud and honored to be appointed as the leading expert in this field. This system allows for a very smooth transition at the highest quality and provides an economic solution for irregular surfaces. In unique applications, we will also recommend the best selection of molds with CNC processed tamper shoes to meet your needs.

Forging design of tamper shoes- Free surface design

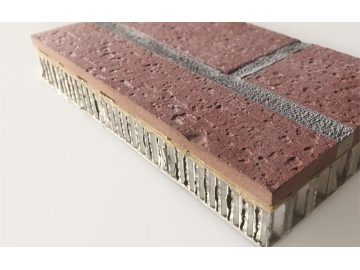

- One-time tool cost

- Optimal optical smooth transition of natural stone.

- Feasible design of heated surface.

- Free surface design

- Cost benefit of one-time produced mold

- The production time is short.

- The design of heated surface is feasible.

- Tamper shoes hardening (62-68 HRC)

- Min.hardening depth is 1.2mm.

- Nitrogen treatment (62-68 HRC) of tamper shoes

- The minimum hardening depth is 0.4mm.

- There is almost no residual stress compared with surface hardening.

Related products

Send Message

Most Recent

More

Other Products

Videos