C25/D25 Series Hydraulic Cylinders for Metallurgy Equipment

We have been proudly manufacturing these high-pressure, heavy-duty hydraulic metallurgy cylinders for over one score years. Now our C25/D25 series hydraulic cylinders offer proximity switches and built-in sensors for your choice.

Working fluids: mineral oil, ethylene Glycol based water solution, or other media

Maximum working pressure: 25Mpa hydrostatic pressure test Ps=37.5Mpa

Design temperature: -20°C~ 80°C

Viscosity: 2.8mm2/s ~380mm2/s (1cst=1mm2/s)

Maximum operating speed: 0.5m/s

Technical Specs

We offer 16 cylinder diameters and 16 mounting styles for choice, meaning that a total of 256 models are available. All models are double-acting single rod cylinders, which are further classed in two groups: tandem cylinders and differential cylinders. Upon your request, we can add protective guard and buffer features.

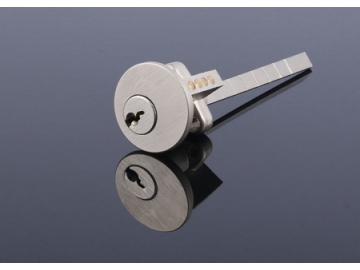

Proximity switches are fitted at both ends of the hydraulic cylinder to control the change of direction at the end of the stroke. The adoption of contact-less proximity sensor allows the switch to send accurate signals when the piston rod is approaching the end of the stroke without physically contacting the rod.

Hydraulic cylinders are often considered motors or actuators in that they are capable of producing work. They commonly called mechanical actuators or linear motors (not hydraulic motors which carry out rotary movement instead of linear movement). Cylinders in diameters between 50mm and 400mm can come with built-in displacement sensor that informs operators of the position of the piston rod in real time. This great addition achieves automated, fast, and accurate motion control.

Built in compliance with lISO and GB standards, the hydraulic cylinder offers sizes and mounting styles meeting international steel plant standards. The cylinder offers a perfect alterative to those from REXROTH, FOSSA, and ELRAM.

Seal kits and guide sleeves are imported from international companies.

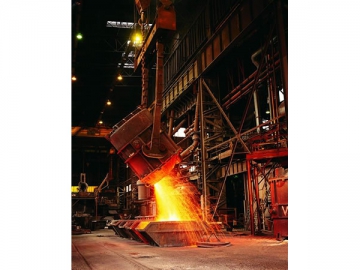

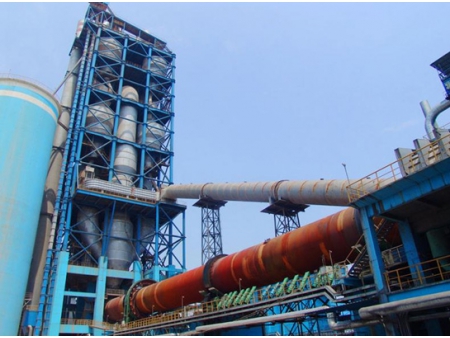

Application Examples