Industrial Gas Analysis System

The process gas analysis system is designed according to specific working conditions and sample gas conditions. This system contains two primary parts: the process analysis instrument, and the sampling pretreatment device, and an overall structure of 5 parts: sample gas acquisition unit, sample gas pretreatment unit, calibration unit of analytical instrument, process analysis instrument and measurement and control unit.

HFSR has been engaged in gas analysis industry for more than 15 years, allowing us to meet a variety of customer needs. The process gas analysis system is an example of system engineering containing a work series, including analysis system design, software development, analysis instrument manufacturing, on-site installation guidance, user training and more.

The process analysis system satisfies multipole harsh engineering application environments, and is used to quickly and accurately analyze the gas composition. It can also be used in extreme environments such as high temperature, high dust, high moisture, high pressure or negative pressure, corrosion, oil contamination, or explosive environments. This makes it ideal for use in the coal chemical industry, petrochemical industry, and chemical fertilizer, metallurgy, building materials, power plants, pharmaceuticals, environmental protection and scientific research fields.

- The sampling probe requires no maintenance, is corrosion resistant, wear resistant, block resistant, and offers multi-probe alternative sampling and continuous analysis.

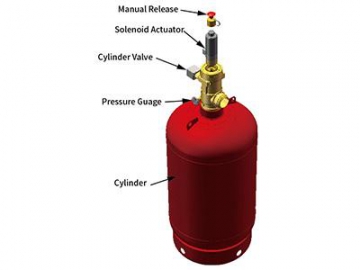

- The solenoid valve is controlled by PLC, and the filter element of the sampling probe is regularly blown back by compressed air.

- A new dry sampling technology will reduce the probability of blocking the sampling pipeline and avoid the loss of soluble components in process gas(Process Gas).

- Multiple filters can remove dust, tar, water and sulfide.

- Uses rapid condensation measures to reduce the loss of soluble gas components.

- The sample gas pipeline is made of high-quality stainless steel and is equipped with a double-clamp sleeve joint. Great air tightness, long service life and strong corrosion resistance.

- Automatic continuous sampling and processing, low maintenance cost.

- After the sampling process gas enters the pretreatment system, some of it will be discharged, thus improving the gas flow rate in the sampling pipe, and reducing analysis lag time caused by a long pipe.

- The sampling pipe is made of a corrosion resistant material with heating and temperature control functions. In requested cases, the heaters and temperature controllers are explosion resistant.

- FCS and PLC automatic control. Automatic control functions such as automatic patrol inspection, automatic drainage, automatic alarm, self-diagnosis, automatic fault treatment and safety interlocking.

- Response time: depends on the gas analysis system design, usually is 30~60s

- Output signal: 4~20mA/RS232/RS485/GPRS

- Sample gas:

1. Temperature: <1400°C

2. Pressure: -17Kpa~ +40Mpa

3. Flow rate: >60L/h - Working conditions:

Temperature: 5~ 45°C (When the ambient temperature< 5 °C, heating. When the ambient temperature > 45 °C, freezing.)

Relative humidity: £85%RH - Safety performance

Insulation resistance >5MΩ