Hydraulic Cylinders for Uncoilers and Recoilers

The hydraulic rotary cylinder provides reliable solutions for expanding mandrels used in coil processing applications. Changjiang’s rotating hydraulic cylinder is most often placed in expand and collapse uncoilers and recoilers for cold rolling operations that deal with copper, steel and aluminum. Quality micro-gap seals ensure no pressurized hydraulic fluids leak into the gap between the shaft and the bore it fits in. As the hydraulic cylinder rotates at a high speed, working fluids are transferred to cylinder for leak-tight performance.

Technical Specs

Rated Working Pressure: 10Mpa

Rated Temperature: -20°C~ 80°C

Seal Kit

Main seals come from MERKEL, combining U-cup seal and Glyd ring. The fluid rotary joint, which transfers hydraulic fluids from a stationary source to the rotating cylinder, comes with rotary oil seals to ensure minimized oil leakage.

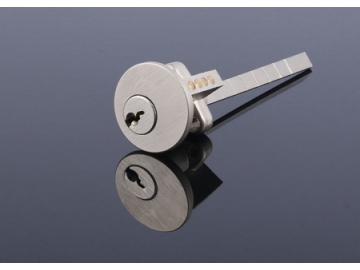

Piston Rod

Precision honed piston rod is made of high-strength carbon steel. Based on a design concept that intends to improve the rod’s strength, we subject our piston rod to a series of heat treatments, chrome plating, and CNC polishing so the resultant product can obtain an excellent surface finish. A smooth rod surface preserves the oil film, which in turns extends the life of sealing elements.

Cylinder

The forged hydraulic cylinder is constructed from high-strength alloy steel that has been through quenching and tempering process. Depending on the specific strength and size requirements, we will vary the wall thickness of the cylinder. The internal surface of the hydraulic cylinder undergoes roller burnishing to achieve optimal hardness and surface finish which tends to minimize friction and extends the life of sealing elements.