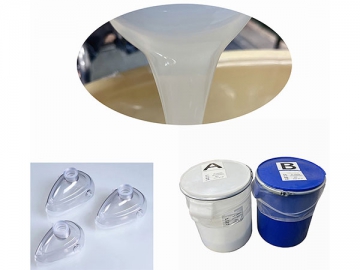

High Transparent LSR (Coating)

Request a Quote

Applications

This liquid silicone rubber (LSR) is used as coating materials for electrical and electronic components, sponge sheets and fiberglass cloth. It is suitable for applications requiring high transparency.

Features

- Rapid vulcanization, good dimensional stability and processability;

- Non-toxic and safe, food grade;

- High tear strength;

Approvals

ROHS, REACH, FDA, CA65, EN71-3, EN14372, PAHS, PFOA, CPSIA, etc.

Test

Rheometer test, 120℃, 5min

Technical Data

- Model:

HT-T9200A/B - Appearance: Translucent

- Viscosity: 2W-3W

- Hardness (Shore A): 20

- Density (g/cm3): 1.06

- Tensile strength (Mpa): 6

- Elongation (%): 700

- Tear strength (K N/m): 15

- Model:

HT-T9300A/B - Appearance: Translucent

- Viscosity: 2W-3W

- Hardness (Shore A): 30

- Density (g/cm3): 1.08

- Tensile strength (Mpa): 6

- Elongation (%): 700

- Tear strength (K N/m): 15

- Model:

HT-T9400A/B - Appearance: Translucent

- Viscosity: 2W-3W

- Hardness (Shore A): 40

- Density (g/cm3): 1.1

- Tensile strength (Mpa): 8

- Elongation (%): 650

- Tear strength (K N/m): 20

- Model:

HT-T9500A/B - Appearance: Translucent

- Viscosity: 2W-3W

- Hardness (Shore A): 50

- Density (g/cm3): 1.12

- Tensile strength (Mpa): 10

- Elongation (%): 600

- Tear strength (K N/m): 30

- Model:

HT-T9600A/B - Appearance: Translucent

- Viscosity: 2W-3W

- Hardness (Shore A): 60

- Density (g/cm3): 1.12

- Tensile strength (Mpa): 10

- Elongation (%): 450

- Tear strength (K N/m): 30

- Model:

HT-T9700A/B - Appearance: Translucent

- Viscosity: 2W-3W

- Hardness (Shore A): 70

- Density (g/cm3): 1.14

- Tensile strength (Mpa): 8

- Elongation (%): 400

- Tear strength (K N/m): 25

- Model:

HT-T9800A/B - Appearance: Translucent

- Viscosity: 2W-3W

- Hardness (Shore A): 80

- Density (g/cm3): 1.2

- Tensile strength (Mpa): 7

- Elongation (%): 260

- Tear strength (K N/m): 15