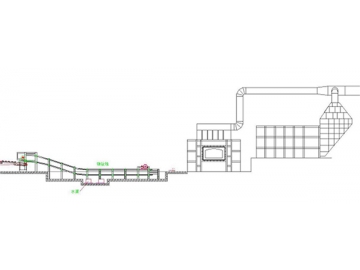

Hydraulic Cylinders for Continuous Casting Plant

In steel plants, the hydraulic cylinder is a critical part of the continuous casting line for processing billets, blooms and slabs. Clamps, hold-downs, vibrator molds, and ladle lifts all require the use of a reliable hydraulic cylinder to provide linear motion.

Technical Specs

Rated Working Pressure: 21Mpa

Design Temperature: -20°C~ 80°C

Sealing System

Seals are of such well-known brands as PARKER and MERKEL. Other seal brands can be used upon your request.

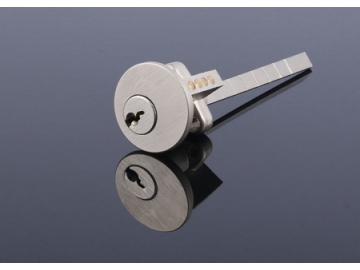

Piston Rod

Made of high-strength carbon steel, the precision honed piston rod owes its excellent strength, hardness and surface finish to the series of processes it undergoes, including heat treating, chrome plating and CNC polishing. A smooth surface helps preserve the oil film for an extended sealing life. Due to the high frequency of vibration needed for the vibrating cylinder, tungsten carbide power is sprayed onto the surface of the piston rod for increased hardness and wear resistance.

Cylinder

The forged cylinder is made of high-strength alloy through quenching and tempering. Wall thickness is varied depending on the required strength and size. Internal surface has been burnished to achieve optimal hardness and surface finish, which tends to minimize friction and prolongs service life of seals. For vibratory cylinder, its internal surface has undergone nitriding to enhance hardness and wear resistance.